![]()

|

George

Clews and Co Ltd

|

Location and period of operation:

|

George

Clews and Co Ltd |

Tunstall |

1906 |

1961 |

|

Earthenware manufacturer. Originally at Burslem and then at the Brownhills Pottery, Tunstall, Stoke-on-Trent, England.

|

George Clews Co. Ltd. was first registered in 1906 as 'Jet Manufacturers'. The 'jet' in question was a red clay, dipped in a cobalt glaze, which on firing became the then fashionable jet black. Their primary products were teapots. The company was run by George's son Percy (Managing Director), and his partner Henry Preece (Sales Director). The Works Manager (and another director) was David Capper, one of the key creative personnel at Clews. He had a great interest in the chemistry of glazing and by 1913 he was working hard on establishing the production of 'artistic pottery' at affordable prices. Perhaps he had in his sights the unsatisfied demand of the burgeoning middle class who aspired to purchase wares of the quality of the much admired Ruskin Pottery, which was hand-thrown and expensive. Capper's solution was to produce in commercial quantities slip cast oriental style shapes to which his experimental crystalline and opalescent glazes could be applied.

It was this art glazed pottery that was first given the name Chameleon Ware in 1914. The origin of the name is uncertain but anecdotally it is said to derive from the changes in the glaze colours during firing.

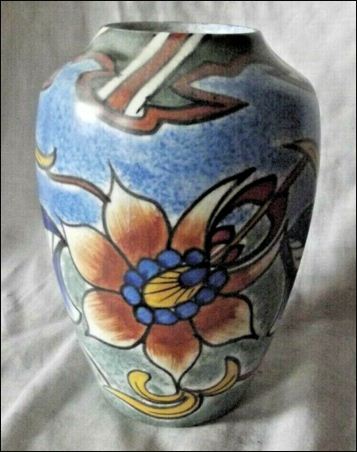

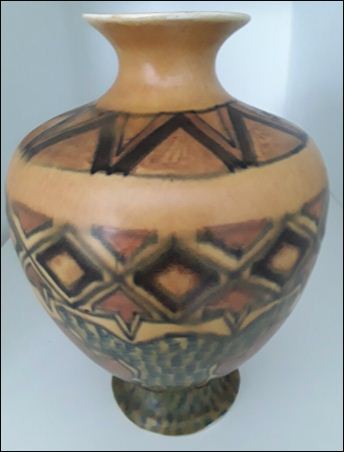

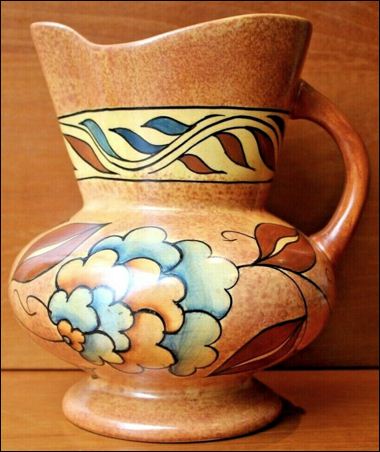

Wounded in the '14 -'18 war, David Capper returned to Clews in the early 1920's and it was then that the bold, hand-painted designs were introduced. Evidence from paintresses employed at Clews suggests that it was David Capper, together with Laura Robinson, ('The Missus' in charge of the decorating team), who originated the designs. Whoever was responsible, it is clear from the shapes that were adopted, such as the 'Persian leather bottle', the 'Graeco-Celtic Flagon' and the exotic 'oil lamps' as well as the oriental and Egyptian inspired patterns, that the creative talents working at Clews were very responsive to the many exciting archaeological discoveries being made at this time. These distinctive designs, along with the beautiful semi-matt glazes which are characteristic of Chameleonware, became very successful.

In 1926 a gold medal and diploma were awarded at the Philadelphia Exhibition for "originality of design" and a year later, the Pottery Gazette reported that after fourteen years of experiment and experience with Chameleonware, "Clews offer a line of ornamental wares which, from the dual aspect of price and quality, is exceptional". Chameleon Ware went on to become 80% of the factory's output.

In the early 1930's the trade press noted the introduction of glazed animal shapes, mostly in a mottled or vermilion splashed green. The majority of these were reptilian (real or imaginary, see above) and intended as garden or conservatory novelties. They included a most engaging chameleon on a log, which is very much sort after by collectors today.

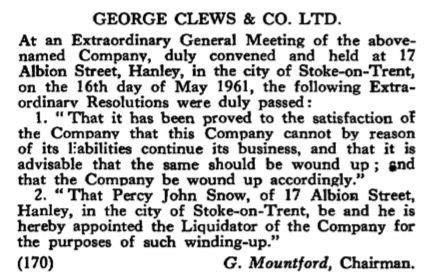

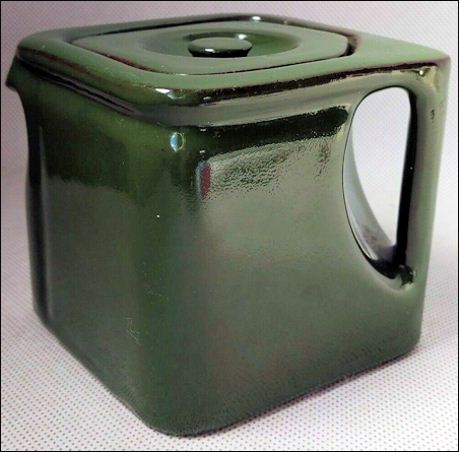

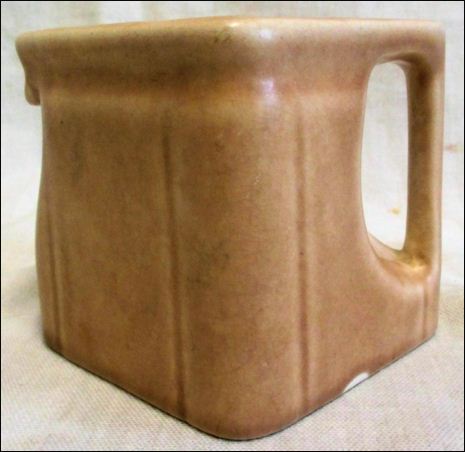

Meanwhile, the firm continued and expanded its mainstay production of teapots (including the famous Cube teapot produced under license for the Cunard Line) and other tablewares. These lines were retained when the outbreak of war in 1939 caused a major re-organisation of the whole ceramics industry, but, sadly at this point, the production of the vibrant and original hand-painted Chameleon Wares ceased forever. Percy Clews died in 1942 and despite attempts to modernise production and find a new direction after the war, the company faltered and eventually went into liquidation in 1961.

References: Chameleon Ware Art Pottery -Hilary Calvert, Schiffer; Encyclopedia of British Art Pottery 1870 -1920 - Victoria Bergesen, Barrie & Jenkins; Collecting Art Deco Ceramics -Howard & Pat Watson, Francis Joseph.

Clews operation during the Second World War During WW2the business was designated as a nucleus firm in 1941 and production continued during the war:

"When I joined Richards Tiles in 1941, wartime fuel economy restrictions were in force. These resulted in all ware produced at Clews being fired at the Brownhills factory of Richards Tiles. There were two products. One was a red body teapot of traditional shape and having a transparent glaze, The other was a white body teapot having the spout in a top corner and a handle recessed into the vertical length of the opposite corner. This pot was glazed in white and went to the Cunard shipping line.The dried clay teapots were placed on boards at Clews and carried across the road on mens' shoulders to Richards for biscuit firing on top of the tile load of the biscuit kiln. They were taken back to Clews by the same means, glazed and returned to Richards for their second firing, situated as a top layer on one of our glost kilns. All tile movement at the Richards factory was by conveyor and so, even in those days, boards on shoulders seemed primitive. However, road traffic was so very light that the system was entirely practical and enabled George Clews to carry on manufacture.

When I returned to Richards in 1948 the practice had, of course, stopped. Nevertheless, for many years afterwards I was offered and drank tea from both types of pot still being used in hidey-holes at all the Richards' factories."

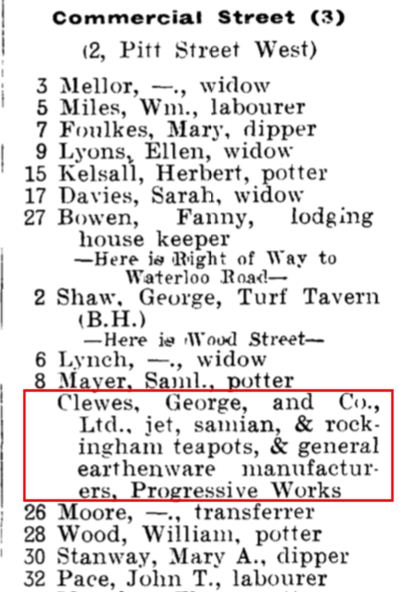

Clewes, George, and Co., Ltd.,

jest, samian, & rockingham teapots,

& general earthenware manufacturers,

Progressive Works

Note the misspelling of Clews

from..... 1907

Staffordshire Sentinel

'Business Reference Guide to The Potteries, Newcastle & District'

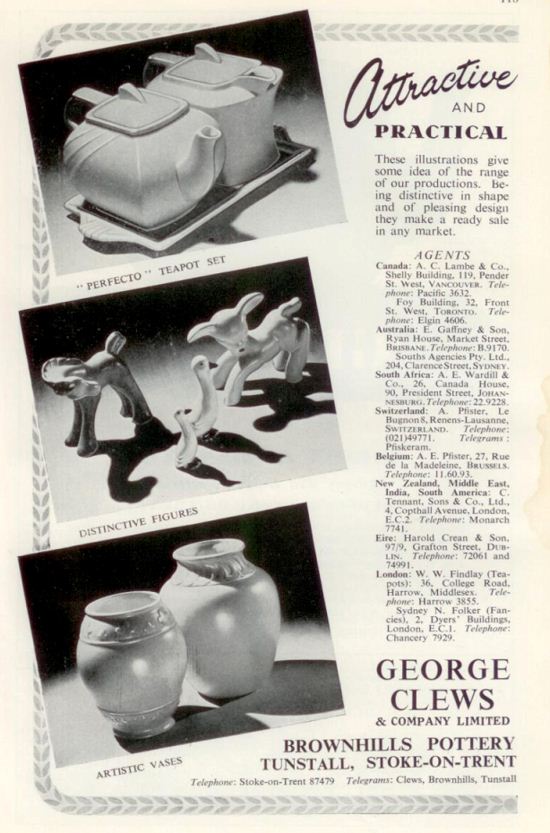

Attractive and Practical

George Clews & Company Limited

Brownhills Pottery

Tunstall, Stoke-on-Trent

1947 advert - Pottery Gazette Reference Book

the same advert also appeared in the 1951 edition

The London Gazette

19th May 1961

notice of appointment of the

Liquidator

|

|

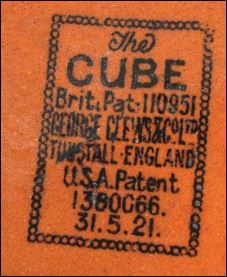

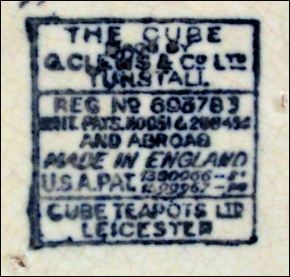

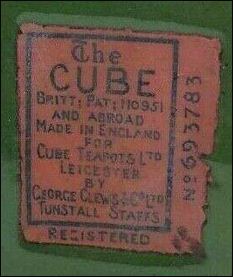

examples of the Cube Teapot produced by George Clews & Co Ltd

The Cube George Clews & Co Ltd Tunstall - England |

The Cube made by George Clews & Co Ltd Tunstall Cube Teapots Ltd Leicester |

The Cube Made in England for Cube Teapots Ltd Leicester by George Clews & Co Ltd Tunstall Staffs |

Chameleon Ware vases and jugs

| In 1926 a gold medal and diploma were awarded at the Philadelphia Exhibition for "originality of design" and a year later, the Pottery Gazette reported that after fourteen years of experiment and experience with Chameleonware, "Clews offer a line of ornamental wares which, from the dual aspect of price and quality, is exceptional". Chameleon Ware went on to become 80% of the factory's output. |

Chameleon Ware tea and dinner

accessories

photos courtesy: My Butler's Pantry, New Zealand

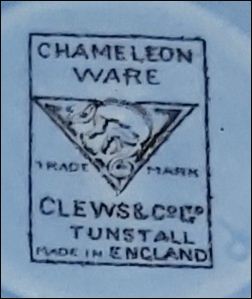

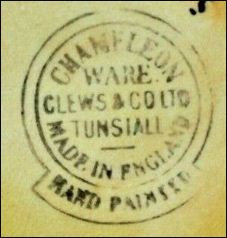

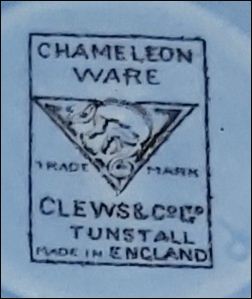

Chameleon Ware

Clews & Co Ltd

Tunstall

Made in England

Style of mark introduced

around 1935

manufacture of Chameleon Ware ceased around 1939

Soup bowls & plates |

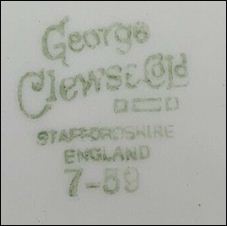

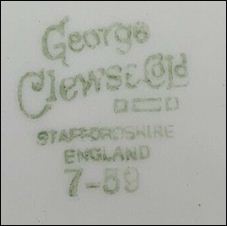

George Clews & Co Ltd Staffordshire England the 7-59 is the date of manufacture: |

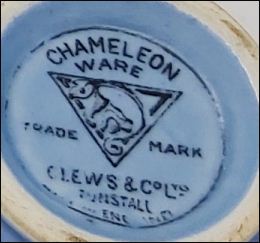

Marks used on ware for identification:

Chameleon Ware

Introduced around

1912/3 production

of Chameleon Ware ceased around 1939

Pastelle Ware

trade name list in 1947

directory

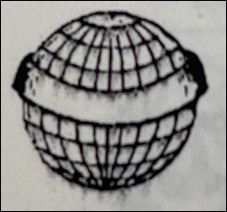

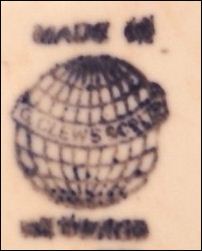

George Clews & Co

Ltd

globe mark usually with the

company name

or pattern name on the centre band

1906+

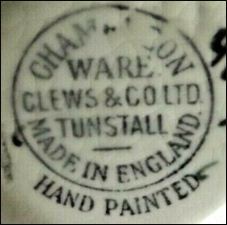

Chameleon Ware

Clews & Co Ltd

Tunstall

Made in England

Hand Painted

Chameleon Ware was introduced around 1912/3

this style of mark was introduced c.1935

production of Chameleon Ware ceased around 1939

Clews & Co Ltd

Made in England

1935+

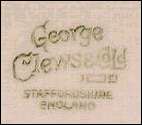

George Clews & Co Ltd

Staffordshire England

1947-61

sometime the month-year of manufacture is included

Questions, comments, contributions? email: Steve Birks