![]()

|

|

|

|

|

Stoke-on-Trent - photo of the week |

Advert of the Week

Potworks of the Week

George Goodwin & Son, Westwood Mills, Lichfield Street, Hanley

Potters' Millers, Established 1848

|

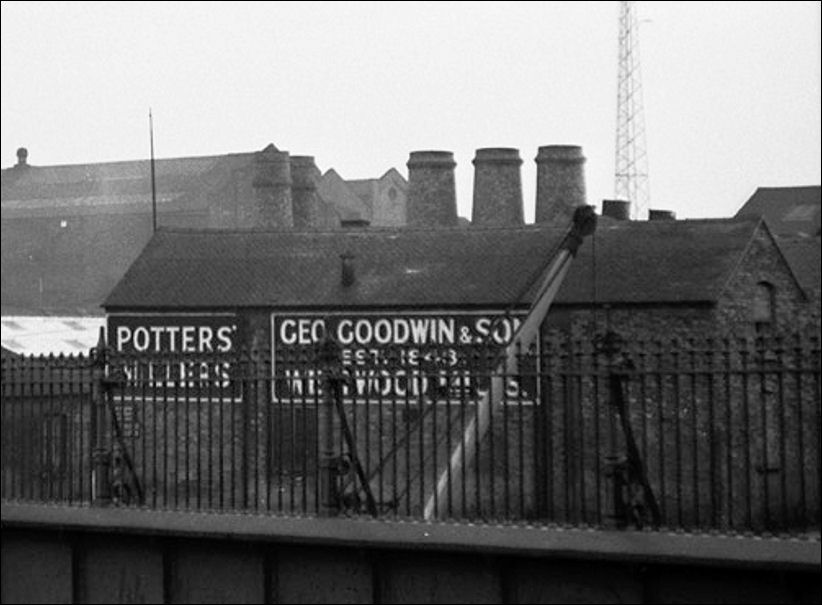

George Goodwin & Son,

Westwood Mills, Hanley

in the foreground are the railings of the bridge over the Caldon Canal

in the background is Hanley Electric Works

photo: 1966 - Ken & Joan Davis

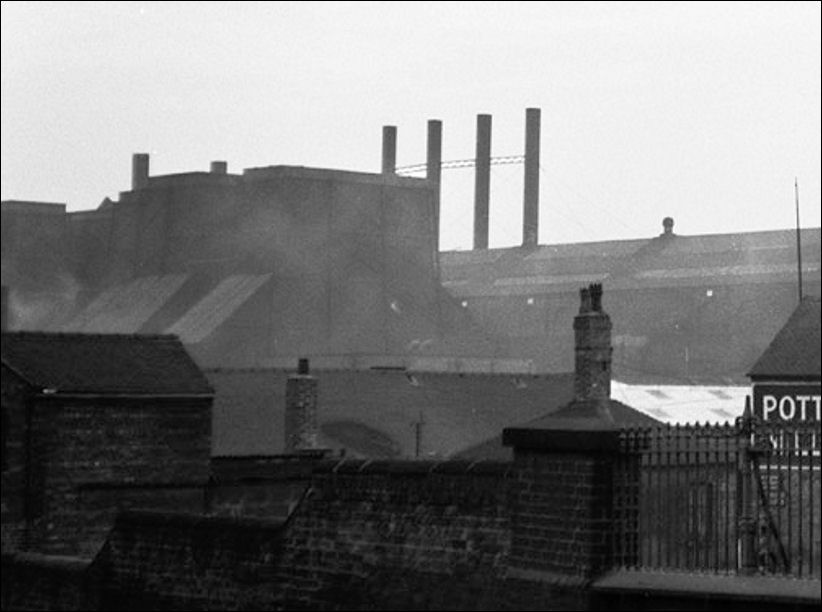

the same view in 2010 - the

cement batching plant which replaced the mill

closed c. 2009, the final buildings are awaiting demolition

the Caldon Canal is to the right, behind the mill the electric works have

been replaced by flats

|

|

the remains of the mill off

Lichfield Street and next to the Caldon Canal

Geo. Goodwin & Son,

(established 1848)

Grinders of Potters' Materials

Consall, Cheddleton and

WESTWOOD MILLS

advert from: 1907 Staffordshire Sentinel 'Business Reference Guide to The Potteries, Newcastle & District'

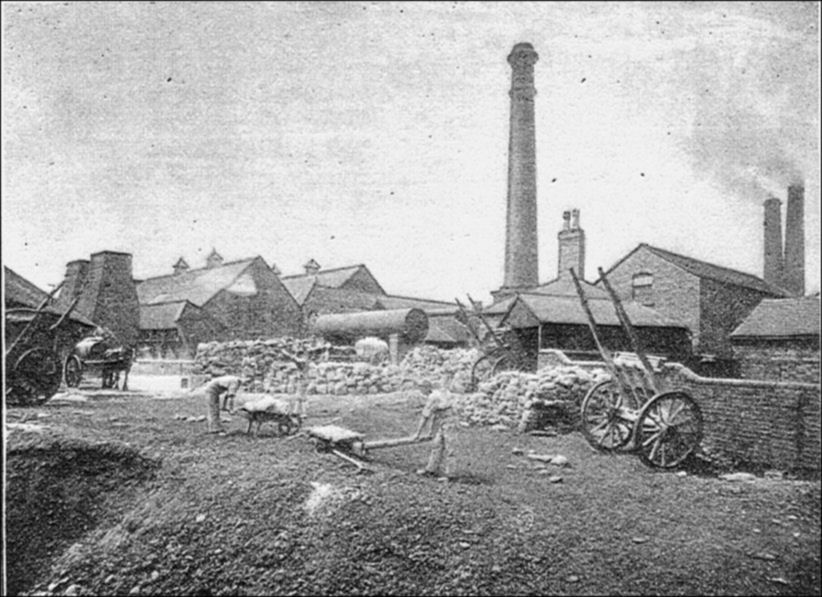

behind the mill can be seen the

bottle kilns of the Trent Pottery, established in 1867 by Livesley & Davis

behind and to the left can be

seen the Hanley Electric Works

Westwood Mills in 1893

|

A descriptive account of

The Potteries (illustrated) Messrs.

George Goodwin and Son, Potters' Material Grinders

"In any attempt to offer a descriptive account of the manufacture of china, porcelain and earthenware, it is necessary to trace the history of the treatment to which the raw materials employed are exposed.

The material treated by this firm include flints collected off the English and French coasts and Cornish stone from Cornwall. Of the substance known as flint, we need say but-little, as its leading properties and characteristics are pretty generally known to even the least erudite reader of these pages. But Cornish stone requires a word of description. It is composed of quartz, partially decomposed felspar, and a talcose material. It is quarried and sent direct to the Potteries in its native state, without any preliminary dressing, or other preparation there, of course, it requires grinding and special treatment before it can be used by the potters in making the many beautiful articles peculiar to their art. At Messrs. George Goodwin and Son's establishment the machinery employed in the grinding of the before-mentioned ingredients is of tho most powerful and modern character, which, considering tho nature of the material to be dealt with, is a fact that will be readily understood, a fine compound engine being required to supply the motor force.

The trade of the firm lies among the various pottery establishments of the district. The business under our notice is one of old and honourable associations. It was founded some forty years ago by the father of the present principal, and by careful administration the business has become the largest of its kind in the neighbourhood of the Potteries. A number of barrel-shaped carts are employed in distributing the prepared material to its various destinations in the Potteries district. The house exemplifies in the most perfect manner the process of grinding preliminary to all porcelain and earthenware manufacture, and its business is an essential adjunct to the staple trade of the district." |

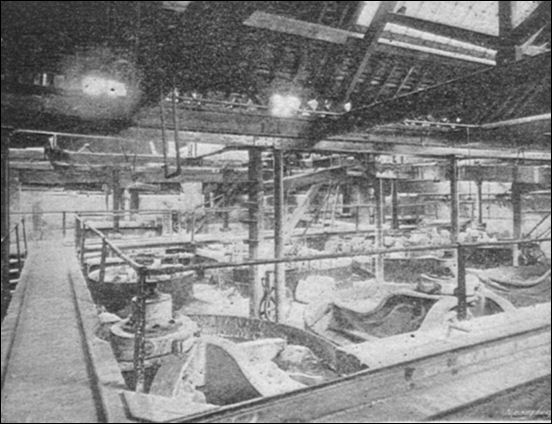

the interior of the mill

the cement batching plant alongside the

Caldon

Canal - in May 2008

[since demolished]

one of the conveyors and

bagging plants -

in the lower right can be seen the bridge on Lichfield Street

|

related pages Hanley Electricity Works, Bethesda Road, Hanley The Bridge Inn on Lichfield Street also see.. Advert of the Week |