The Middleport Pottery of

Burgess and Leigh (opened 1888)![]()

![]()

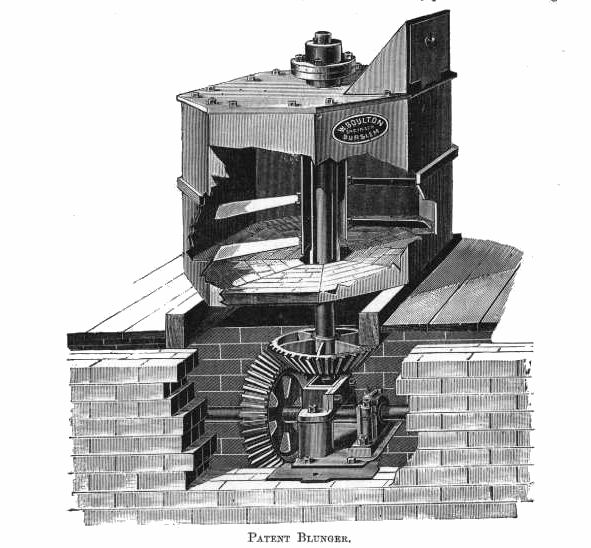

The blunger - washes the clay and converts it to slip

![]()

![]()

![]()

Next: the filter press

Previous:

the linkage from the steam engine

To improve production and the working condition of their employees, Burgess and Leigh installed the latest mechanised processes in their potworks - the blunger was one of them.

William Boulton designed the blunger and patented it in 1874.

A doctors report to the 1840 commission into child labour in pottery works stated:

" 'Slip making', or preparing the clay, is another unwholesome occupation. "The clay" is prepared by boiling the composition to a proper consistence on kilns, and during the process of evaporation, the room is filled with dense aqueous vapour. The men engaged in this branch suffer severely from winter cough and chronic bronchitis; and but few of them, if they survive, are able to perform much labour after the age of 60".

The blunger washes the clay and converts it to slip.

The slip is clay in a thin watery suspension - this makes it easy to

remove the impurities and to get a consistant clay

At one time blunging was an arduous

manual job

The blunger as originally designed by William Boulton

"....the patent blunger,

for washing the clay and reducing it to slip.

The old method of blunging the clay was a manual operation, very laborious and

injurious,

whereas Mr. Boulton's is a machine worked by steam power,

which does the work more effectually, and in less time, and also at considerably

less cost."

from an 1893 trade journal

![]()

![]()

![]()

Next: the filter press

Previous:

the linkage from the steam engine