Photo

of the Week

Potworks of the Week

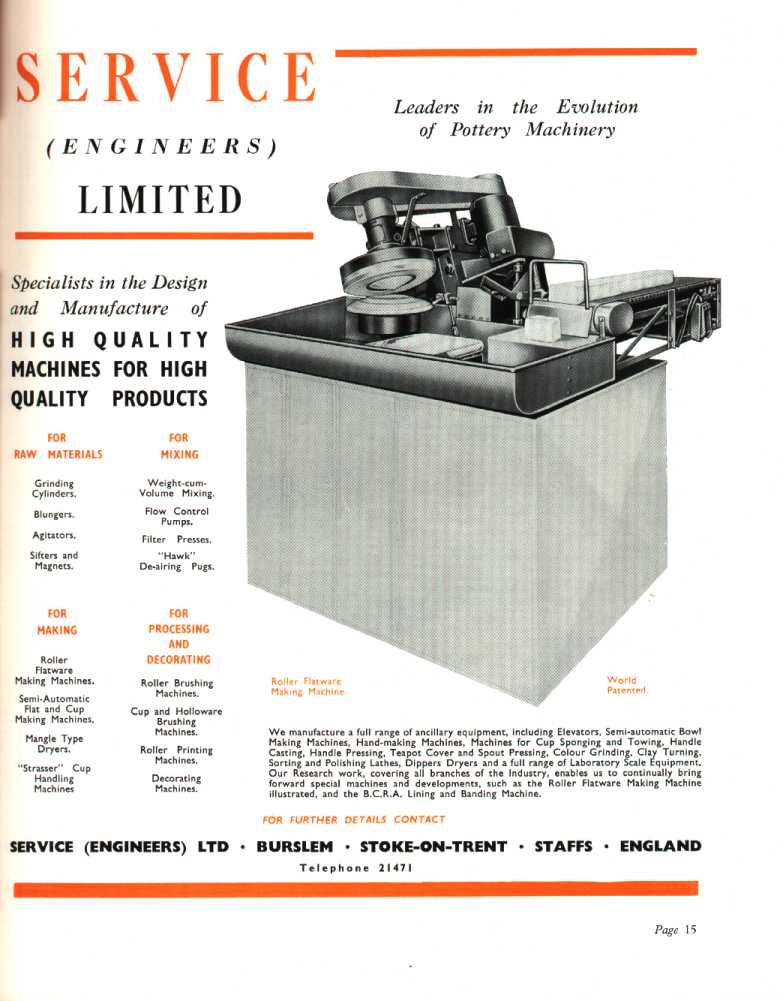

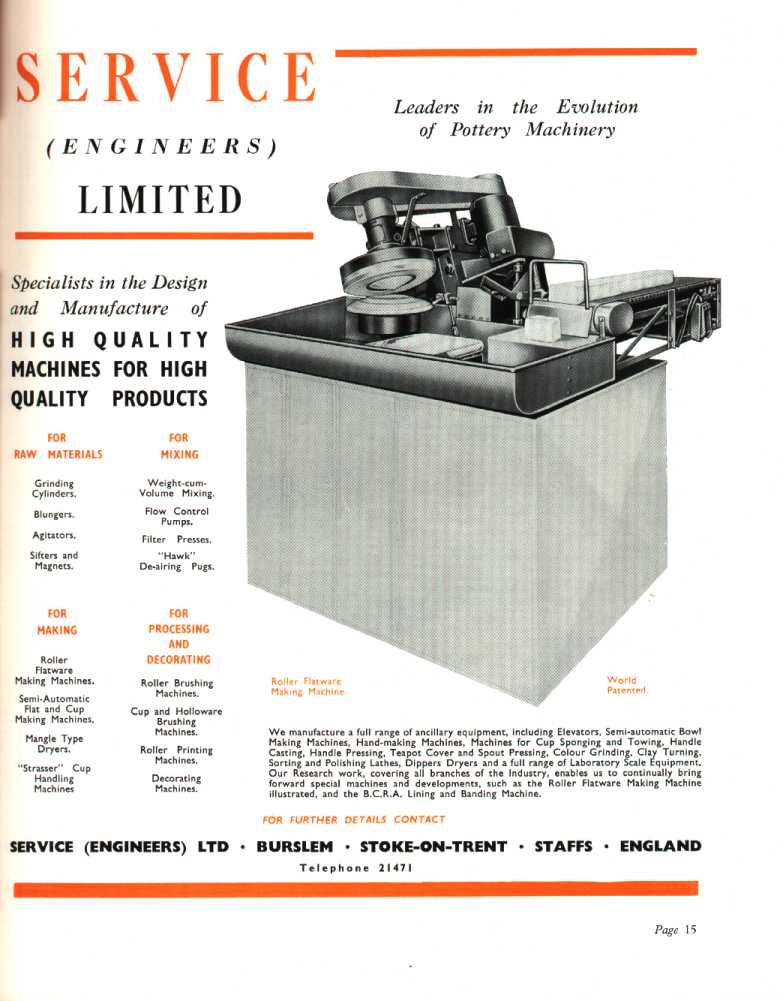

Service (Engineers) Ltd,

Burslem

Service (Engineers) Ltd, Burslem

from: Prestige and Progress - A Survey of

Industrial North Staffordshire

1955 publication of North Staffordshire Chamber of Commerce

|

Steam powered

jiggers (and jolleys - for producing hollow ware) were known of in

the 1840s but there was much worker resistance to their

introduction. The first mechanical jigger replacing hand power was

the Porteus, driven by long lengths of shafting and belts. The

potters were charged a weekly rent equivalent to the wages they

had paid the boy who powered it before. In 1863 Francis Wedgwood

had a plate making machine presented by a continental potter. The

machine was so popular that within 15 years most of the large

companies used it.

To work to capacity

the jiggerer needed three boy attendants, and 600-1000 moulds.

One attendant cut

a piece of clay and put onto a revolving surface where it was

batted out by a spreader tool. Another attendant fixed a plate

mould to the machine head. The jiggerer took the clay bat and

threw it onto the plate mould held in the revolving jigger head.

He pulled down the machine arm with the profile tool fixed form

the back. The face of the plate was formed by the mould itself.

The mouldrunner took two made plates to the drying stove and

brought empty moulds back. The third boy would back the plate,

fettling and finishing it, making sure it was smooth all over.

|

|

A jigger for the production

of flatware

at the works of Burgess, Dorling & Leigh

The jigger

manufactured by:

Service

Engineers Ltd

Burslem, Staffs

England

![]()