Blue Jay pattern

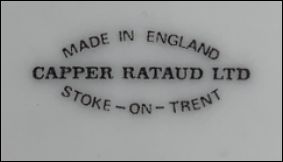

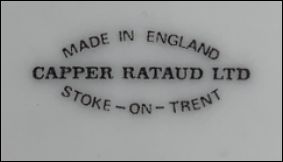

Capper Rataud Ltd

Made in England

Stoke-on-Trent

The Lithos

for this pattern were supplied by Capper Rataud Ltd,

an important

lithographic and screen print manufacturer based in Stoke on Trent.

Simple

explanation

of offset lithography

|

1. Basic Principle

2. Process Steps

-

Design Creation: A detailed design is prepared, often digitally.

-

Plate Preparation: The design is transferred onto a lithographic plate, usually made of metal.

-

Inking and Printing:

-

Ink is applied to the plate.

-

A rubber blanket (offset cylinder) picks up the inked image from the plate.

-

The image is then transferred (offset) onto a paper or decal.

3. Transfer to Pottery

-

The printed paper or ceramic decal is applied to the pottery item by hand or machine.

-

The piece is then fired in a kiln, causing the design to fuse permanently with the glaze

layer

4. Advantages

-

High-quality, detailed prints

-

Suitable for mass production

-

Consistent results with complex designs

5. Applications

-

Decorative tableware

-

Commemorative ceramics

-

Branded pottery items

Multi-Color Process:

-

Separate Plates for Each Color:

Each color in the design requires its own lithographic plate. So, if the

pattern has red, blue, and yellow, then three plates are

needed.

-

Sequential Printing:

The colored inks are applied one after the other, with precise alignment (called registration) to ensure the pattern lines up perfectly.

-

Layering on Decals:

The multicolored image is typically printed onto a single decal paper, which is then transferred to the pottery in one go.

Firing:

|

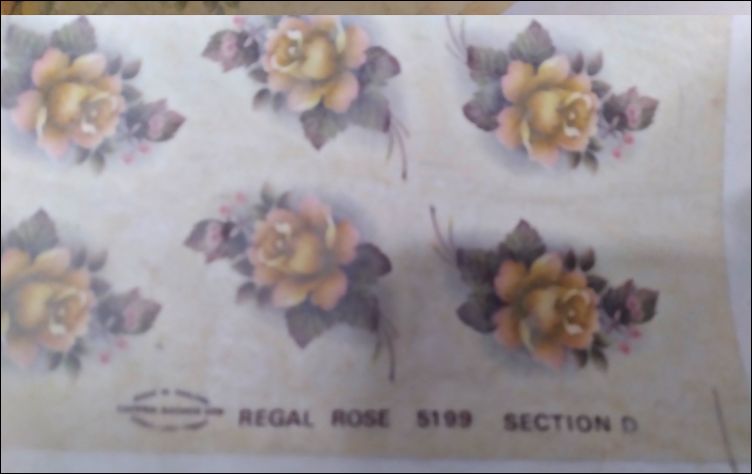

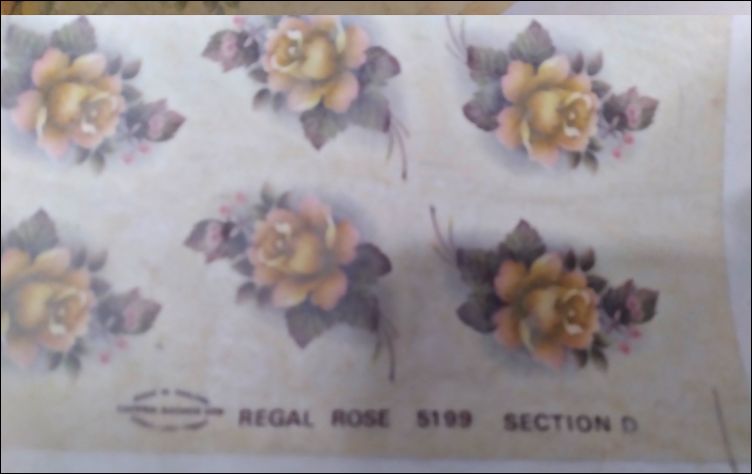

Regal Rose pattern - 5199

The Championship Series..

A Round of

Golf | The Tennis match | A Day at the Races

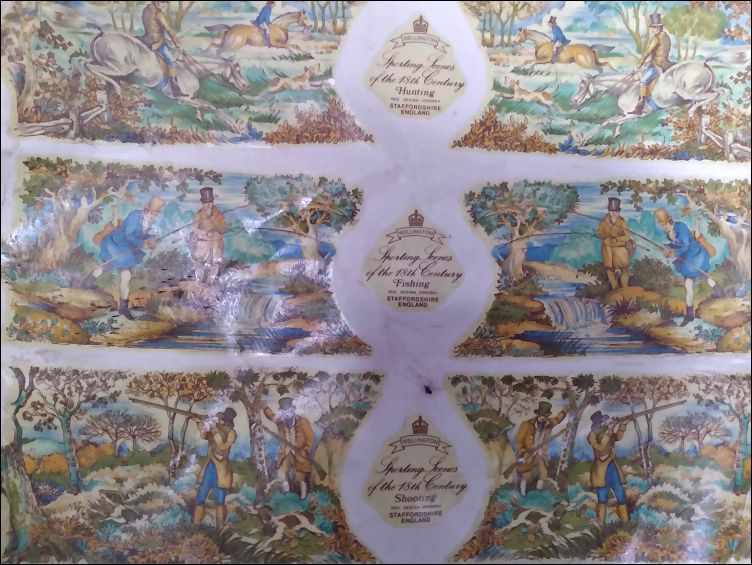

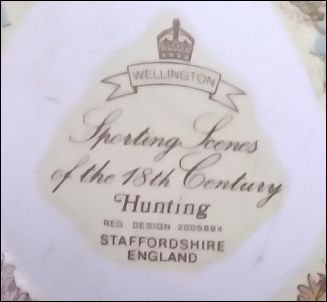

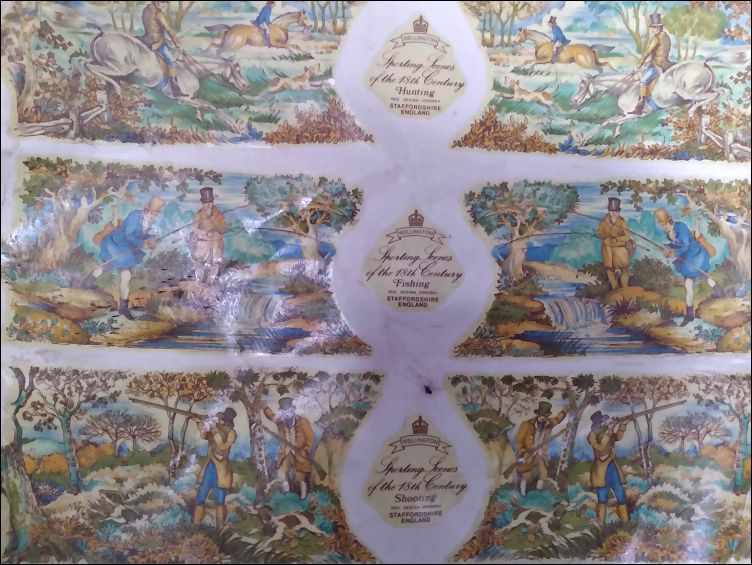

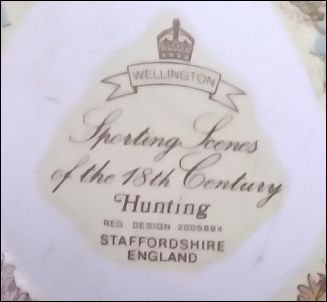

The Sporting Series..

Hunting

| Fishing | Shooting

Questions, comments,

contributions? email: Steve Birks

![]()