|

Brownhills:

Richards

Tiles.....

To

supplement the

Pinnox works, the Brownhills Works was purpose built by

Richards

Tiles Ltd in autumn 1933 and was opened in 1934.

Richards' New Works

at Brownhills, 1937

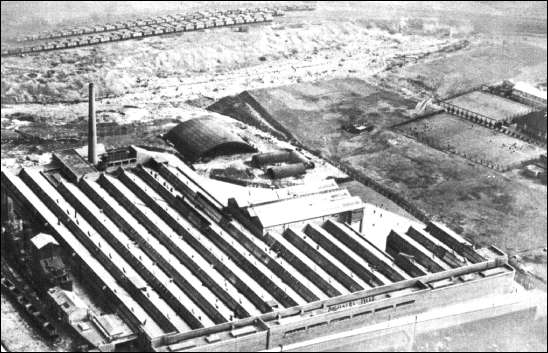

Aerial view of

Brownhills factory

(around 1953)

"In 1933 it was realised that

the demand for Richards tiles was rapidly rising beyond the point at

which it could be satisfied from the

Pinnox Works, and it was decided to lay down an entirely new

supplementary plant. A large site having been acquired at Brownhills

- a few hundred yards from the parent establishment - building

operations were commenced in the autumn of the year mentioned, and

the new factory was opened in the summer of 1934.

Brownhills Works is one of the

best and most up-to-date tile factories in the world. For every

stage of the tile-making process it is equipped with the latest and

best machinery obtainable, no effort and no expense having been

spared to place it on the highest plane of efficiency; and it is

gratifying to be able to add that, if the new factory is a model in

this respect, it is no less admirable in the amenities it provides

for its workpeople, who perform their tasks under conditions of

comfort and hygiene little dreamed of in the industry even a decade

ago. Notwithstanding this, it would be a fundamental mistake to

regard the Brownhills Works as standing alone and the older Pinnox

plant as being relatively obsolete. The progress policy manifested

in the Brownhills venture is no new departure; it has been the

everyday life of the firm for very many years, with the result that

the Pinnox plant has been kept well abrest of the times. Thus the

same standard of quality - a standard which increased efficiency has

enabled us to keep to our traditional high level in spite of drastic

reductions in our selling prices - characterizes equally the

products of the one factory and the other."

From: "A Century of Progress

1837-1937"

a publication to commemorate The Centenary of Richards Tiles Ltd.

Richards Tiles in January 1948

The company was

operating on four sites.

1) Burslem

Mills Co. Ltd was in Federation Road, Burslem. It

supplied calcined and ground flint, ground stone (a fusible

material) and ground limestone, all in slurry form, to the tile

manufacturing units. Calcination of flint was carried out in coal

fired bottle ovens, in which alternating layers of coal and flints

were laid down. Bill Washington, who had started at Richards on

the same day as me, was later to manage this unit and go on to

manage the corresponding units at H & R Johnson.

2)

Hallfield Works was at Festing Street, Hanley. It had

been purchased from T & R Boote in 1947 and manufactured about

three thousand square yards per week of unglazed floor tile. The

manager was Len Washington (brother to Bill above). Firing was by

coal fueled bottle ovens.

3) Pinnox

Works lay between Williamson Street and Woodland

Street, Tunstall. It was divided into Bottom Works and Top

Works.

Bottom Works produced about six thousand square yards per week of

unglazed floor tile and mosaic. Firing was carried out in nine

coal fueled bottle ovens. Arthur Lea was works manager

Top Works produced twelve thousand square yards per week of glazed

wall tile and about ten thousand pieces per week of bathroom

fittings. The biscuit (first) firing was carried out in five coal

fueled bottle ovens and the glost (second) firing in four

continuous tunnel kilns. The first of these had been laid down in

1925. However, it was not until 1959 that we fired our last coal

fueled bottle oven. Ian Munroe was works manager.

4)

Brownhills Works, Brownhills Road, Tunstall was the

most modern of the units. It was built 1933/34 and manufacture

had commenced in the summer of 1934. By January 1948 production

had been lifted to twenty five thousand square yards per week.

Brownhills factory was considered to be the most efficient tile

plant in the world at that time. All firing was by tunnel kilns.

The nearly 400 foot long “A” biscuit kiln had been brought to 1170

Centigrade in 1934 and was to maintain that temperature

continuously, until repairs were made in 1954. Len Ford was works

manager.

Richards Tiles was self sufficient with its own then-very-modern

transport fleet. However, there remained a relic of a bye-gone era

in the form of horse, cart and Sam Brooks. Sam, clad in sack-bag

apron, together with horse and cart was a familiar sight, daily

plying his way between Pinnox, Brownhills, Burslem Mills and

Tunstall railway station yard. The directorate had decided that

this form of transport would continue until either Sam or his horse

was no longer fit for service. It was a sad day for Richards and

Tunstall when horse Billy had to retire.

Ken Green

|

![]()

![]()

![]()