"This profusely illustrated book will appeal to a very wide range of readers. Not only does it deal with the source and preparation of the many raw materials required by pottery manufacturers in the 19th and 20th centuries, it has a wealth of information on working conditions in the Potteries during that period.

The book is divided into three portions;

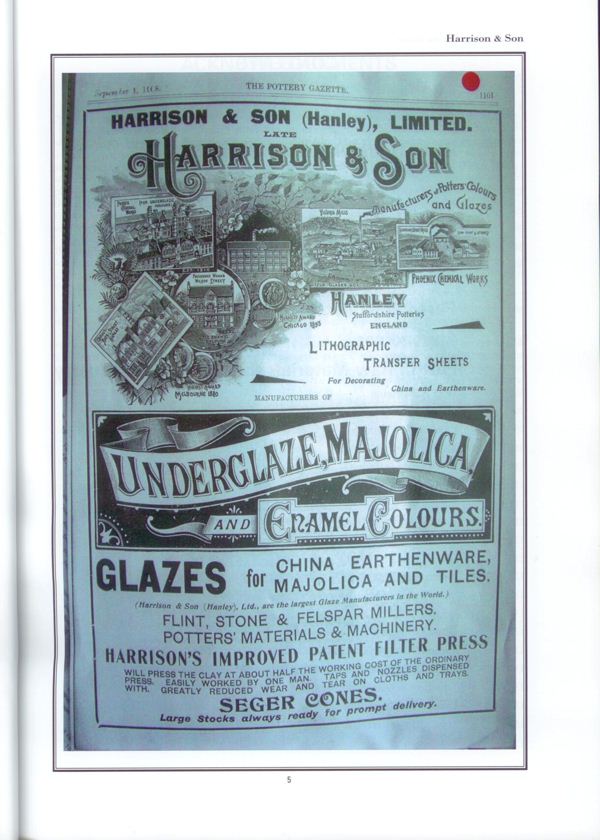

the first of which deals at length with the history of the Harrison family beginning with the founder, William Richard Harrison, who started business in Lincolnshire as a wholesale chemist and how he came to migrate to Hanley to buy a colour and glaze making factory.

Harrison and his son, Thomas William, who provide the title for this book, established an increasingly successful business procuring, preparing and

supplying materials to the local potteries which didn't have their own in-house material processing facilities.

This part of the book is also of interest to those family historians with roots in the Potteries as the large Harrison family became integrated into local affairs by way of marriage, business mergers and the public works of Harrison senior. Many early postcards and photographs are illustrated and anyone with local knowledge will be fascinated by the illustrations of buildings, streets and canal scenes which are now gone for ever.

In 1893 Harrison and Son had a stand at the World Columbian Exposition which launched them into the international market with the result that members

of the family emigrated to the USA and Australia in order to promote the business. The outbreak of the First World War resulted in the same restrictions and staffing difficulties in the pottery industry that were experienced throughout the country as a whole but the story of the business and family continues throughout the first half of the 20th century until the firm was acquired by Goodlass, Wall & Lead Industries in 1963.

The second section of the book is devoted to recording the memories of employees of Harrison & Son during the 1950s and 60s. Many of these memories illustrate the difference in working conditions between the middle of the 20th century and today.

The health and safety at work issues were certainly much more lax at that time but the paternalistic benefits enjoyed by those working for a family business contrast strongly with those who now work for faceless companies.

The jobs that are recalled were very varied and spread between the various sites owned by Harrison and Son but provided a great opportunity to retrain for those returning to civilian life after the Second World War.

The last section

concentrates on the products of the various factories beginning with the types of raw materials which were processed. These range from the different types of rock which are ground for inclusion in the pottery body to the various types of naturally occurring silica which are required for glaze recipes. The reason for calcining then crushing flint is also well explained without getting too technical and a fourth section is devoted to milling. The process of preparing frit and glazes is also covered in this last section but the accompanying illustrations are so self-explanatory that the processes are easy to follow.

In conclusion this book is interesting on many levels and should not be judged solely on the title 'Raw Materials for the Potter'. Instead it provides an overview of the enterprise and opportunities which were available to entrepreneurs during a time of technical improvements and expansion in the Potteries."

![]()