|

|

|

![]() back to "The Grand Tour" index

back to "The Grand Tour" index

Neville Malkin's "Grand Tour" of the Potteries

buildings on the

Trent and Mersey Canal

![]()

![]()

![]()

next: Twyfords Cliffe Vale

Works

previous: Bear and Bell,

Shelton

contents: index of buildings in Etruria / Shelton

|

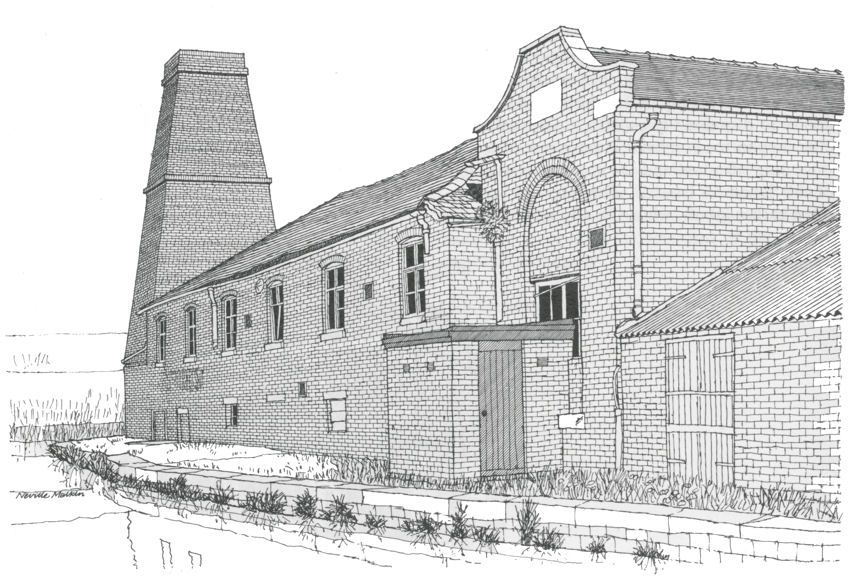

No 80 - The Etruscan Flint Mill

|

Etruscan Flint Mill

pen drawing by Neville Malkin - July

1975

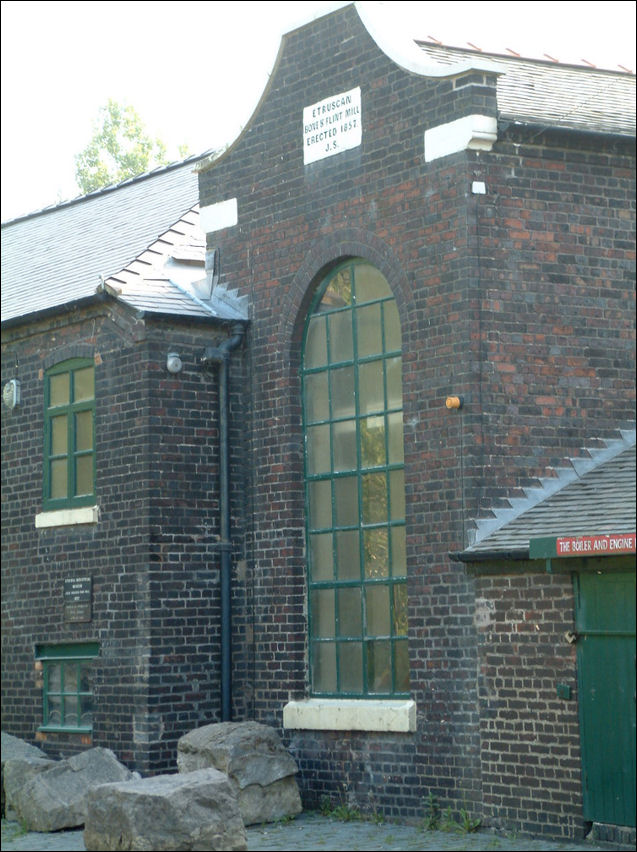

Etruria Industrial Museum,

Lower Bedford Street, Etruria

photo: May 2008

| The Etruscan Mill was built

in 1857 alongside the Trent and Mersey Canal. The Mill's purpose was to

grind materials for the agricultural and pottery industries, such as

cattle bone and flint. Bone meal was used by farmers as a fertiliser.

Ground, burnt bone is added to Cornish stone and china clay at the

pottery factory to make bone china.

The Mill only ceased production in 1972 with the process and machinery virtually unchanged. In 1975 the Mill was scheduled as an Ancient Monument. It is situated at the junction of the Trent and Mersey and Caldon canals. |

|

"This interesting example of industrial architecture, on the banks of the Trent and Mersey Canal adjacent to the Summit Locks, is the Etruscan Flint Mill, erected in 1857. At one time such mills were essential to the pottery industry and quite a common sight, but, alas, very few now exist, although I believe this one, with its superb beam engine, will be reprieved and converted into a museum. The introduction of flint into the manufactory of pottery is shrouded in mystery, but one theory attributes its discovery to Thomas Astbury of Shelton, who, about the turn of the 18th century, stopped at an inn in Dunstable and noticed the soft and delicate nature of fine flint-stone used by an ostler as a remedy for a disorder in his horse's eyes. This suggested to him the idea of using it in the pottery trade. About 1720, considerable improvements were made by using calcined flintstone, at first as a wash or dip, and afterwards incorporating it with the clays. A mixture of flint with the local clays was the basis of the white stoneware which became the staple commodity of the district for several years. The original method of preparing the flint-stone was to pound it into a dry state and then sift it through a fine mesh, but this proved harmful to the workmen. By the mid-18th century, new machinery had been perfected for working the flint which was far more efficient and also eliminated health hazards. The flints were first doused with water to prevent the dust rising and then crushed to the consistency of sand by two giant millstones. The crushed flint was then conveyed into circular vats that contained large iron balls which were driven round by the waterwheel at such speed that the flint was ground as fine as oil. With the introduction of steam engines all previous sources of power, such as windmills and waterwheels, became obsolete." |

Etruscan

Bone & Flint Mill

Erected 1857

J. S.

![]()

![]()

![]()

next: Twyfords Cliffe Vale

Works

previous: Bear and Bell,

Shelton

contents: index of buildings in Etruria / Shelton

|

Related Pages back to "The Grand Tour" index Details of the listed status of the Etruscan Mill

also see.... Etruria:

Josiah Wedgwood & Etruria.

Canals

and Waterways

|