The Middleport Pottery of

Burgess and Leigh (opened 1888)![]()

![]()

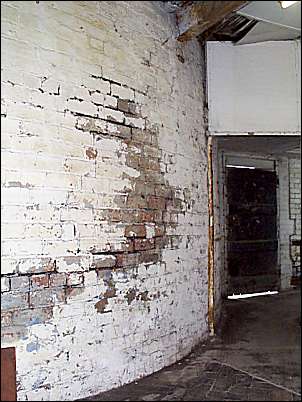

Bottle kiln from inside the factory

![]()

![]()

![]()

Next: the inside of the mangle dryer

Previous: the hand painting department

The bottle kiln encroaches on the inside of the factory |

Kiln as seen from outside There were seven kilns of diffetning types at Burgess and Leigh |

| after

the passing of the Clean Air Acts in the mid 1950's the pottery

manufacturers moved to gas and electric kilns and the coal fired bottle kilns stated to be demolished. this one survived demolition because it was part of the factory wall |

|

Old saggars - fireclay boxes in which the ware was placed during the firing process this protected the ware from the ash and smoke generated during firing in the coal fired bottle kiln |

|

![]()

![]()

![]()

Next: the inside of the mangle dryer

Previous: the hand painting department