![]()

|

William

Moorcroft (Ltd |

Location and period of operation:

|

W

Moorcroft (Ltd |

Cobridge |

1913 |

Active 2025 |

Earthenware manufacturer at

Cobridge, Burslem,

Stoke-on-Trent, England

William Moorcroft at James Macintyre & Co:

Moorcroft 1986-:

|

Also see James MacIntyre and Co

The Moorcroft family

William Moorcroft 1872-1945 |

Walter Moorcroft OBE 1917-2002 |

John Moorcroft (William John Scarlin) -2022 |

Will Moorcroft |

|

William founded the company in 1913. |

When William died in 1945 control of the business passed to the eldest son Walter, who retired in the late 1980s. |

Appointed Managing Director c.1986 - John stepped down from the business in 2006. |

Grandson of William Moorcroft - Will bought the business out of liquidation in June 2025. |

|

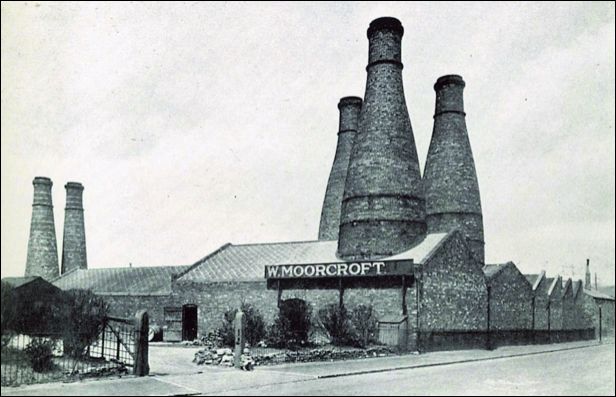

source: photo by Hay Wrightson 1928 |

source: 'Memories of Life & Living' 1999 |

credit: Sentinel Newspaper 2013 |

credit: BBC June 2025 |

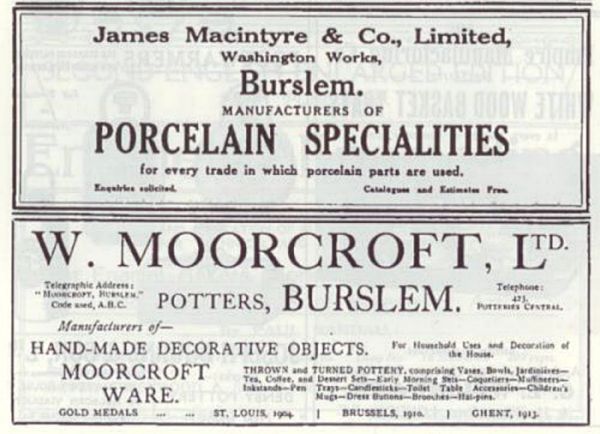

The Pottery Gazette Diary 1917

|

Page 42 of the Pottery Gazette Diary for 1917 showing adverts for both James Macintyre and William Moorcroft - this was after the two parted company in 1912 and Moorcroft started his own business in 1913. Macintyre had reverted to advertising the manufacturer of industrial ceramics whereas Moorcroft was advertising 'Hand-made decorative objects'. |

The Moorcroft factory in

Sandbach Road, Cobridge, Burslem

|

The works were designed to reflect the social and legislative concern for health, hygiene, and functionalism, and were one of the first single storey factories to be built in the Stoke-on-Trent Potteries. It is a single storey factory, nine rooms wide by four rooms deep. The ovens were circular updraught kilns which have no hovel (the bottle shaped brick structure built to fully enclose the oven). No doubt the design of the factory was influenced by the fact that in 1913, the same year the factory was built, William married Florence Lovibond, a local Factory Inspector. The initial small factory was completed for production in ten weeks. Due to interruptions from the First World War, construction was in three stages: the core, including one bottle oven in 1913, and two surrounding structures, with more ovens, in 1915 and 1919-20. Moorcroft chose a site that overlooked Cobridge Park and was alongside the North Staffordshire Potteries Loop Line Railway. |

Only one of the original five bottle kilns remains - which is a listed building |

details of the Moorcroft factory in Cobridge |

advert and article from a 1947 Stoke-on-Trent handbook |

- click the photos for more details -

Moorcroft Nile Street

collectors' shop and manufacturing unit

Google Street View

| Sentinel Newspaper article,

17th April 2001 - 180 new jobs at pottery An expanding pottery firm is to create 180 new jobs and double production over the next four years after building a £3 million factory to target America. Burslem-based Moorcroft, which currently employs 250 staff, expects the purpose-built 30,000 sq ft plant in Nile Street to supply its branded products to the US and Canadian markets. Chairman Hugh Edwards today said the investment could lead to even greater things as it will only satisfy a fraction of foreign demand for the company's brand. Mr Edwards said:

Work on the site, which will double the company's existing 28,000 sq ft manufacturing space, started last March. The firm received £634,000 from the Government's Single Regeneration Budget (SRB)

in addition to its own investment. Moorcroft produces a unique product by applying glazes directly on to wet clay, rather than after a first firing. He said:

Moorcroft has relied on the methods devised by its founder William Moorcroft for

the last century. William first developed the designs that have become famous world-wide when he

worked at the Washington Works owned by James Macintyre in Burslem. By 1900, William was producing his own designs which after 1912, when the Liberty Chain bought the company, received global exposure. The company moved to the Sandbach Road works at Cobridge the same year. He stayed in control of the company until his death in 1945 when the firm passed

to his son, Walter. But attempts to drag the small art pottery into mass production failed and two

years later the firm faced liquidation. They appointed John Moorcroft as managing director to act as an ambassador for the company and boosted annual turnover from around £245,000 to the current five million pounds plus. In 1992, Hugh Edwards become chairman, a year later appointing Rachel Bishop as its new designer. |

Questions, comments, contributions? email: Steve Birks

|

Page created 7 April 2007. Updated: 16 May 2023 - page content significantly updated. Updated: 15 June 2025 - rearranged the introduction and added date headings, added photos of the Moorcroft family, links to other Moorcroft pages, details of the liquidation and buyout. Updated: 21 Sep 2025 - details of production recommencing. |