The Middleport Pottery of

Burgess and Leigh (opened 1888)![]()

![]()

The cup shop

![]()

![]()

![]()

Next: manufacturing 'flat ware'

Previous: sponging the ware

We have moved downstairs to the cup shop which is underneath the casting shop.

the handles which are cast into the plaster moulds need to be trimmed to remove the flash and surplus clay end to ensure every handle is the same size.

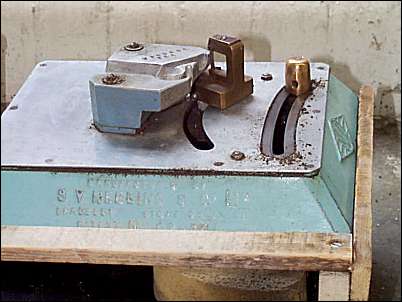

The 'green' handle is trimmed in the jig shown below.

Handles in a plaster

mould

The 'flash' can be seen around the handles

|

|

Cup handle cutter jig |

Handle placed in the jig ready for cutting This is the jig for "Windsor Tea" pattern - a change piece is used for different patterns |

Handle being cut to size |

|

|

|

|

|

|