![]()

|

Myott,

Son & Co (Ltd) |

Location and period of operation:

|

Myott, Son

& Co (Ltd) |

Stoke |

1898 |

1902 |

|

Earthenware manufacturer originally in Stoke, and then from 1902 at Cobridge Stoke-on-Trent, England.

|

Formerly: G. T. Mountford

Subsequently:

Myott-Meakin Ltd

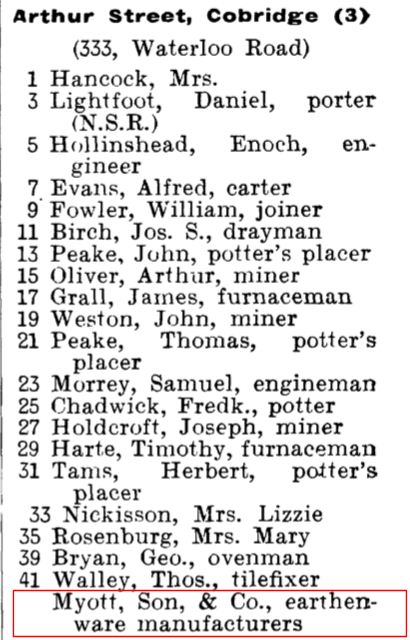

Arthur Street, Cobridge

Myott, Son

& Co., earthenware manufacturers

from..... 1907

Staffordshire Sentinel

'Business Reference Guide to The Potteries, Newcastle & District'

Arthur Street was newly built

c.1901 at the same time

as the new Myott Alexander Works

In the early 1950's Arthur Street was renamed Crane Street.

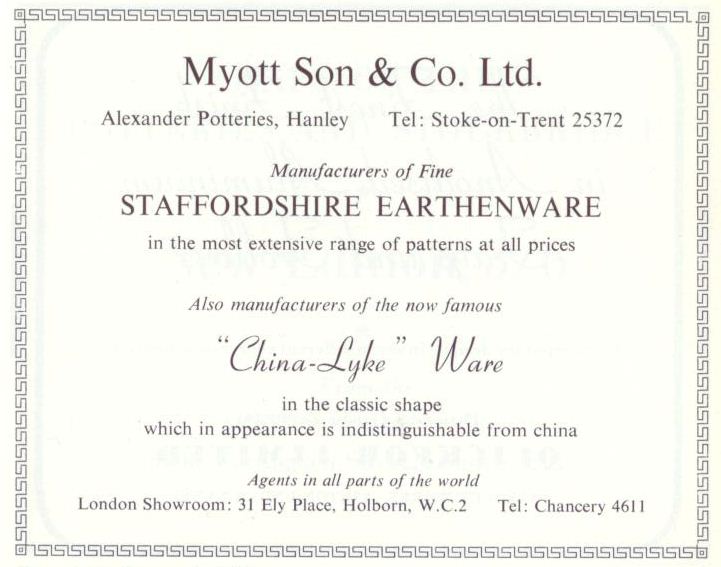

Myott Son & Co. Ltd.

Alexander Potteries, Hanley

Manufacturers of Fine

Staffordshire Earthenware

in the most extensive range of patterns at all prices

Also manufacturers of the now famous

"China-Lyke" Ware

in the classic shape

which in apperance is indistinguishable from china

Advert: The Pottery Gazette Reference Book 1960

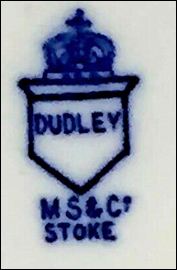

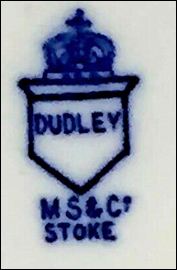

flow blue style plate with gilt - in the 'Dudley' pattern |

M S & Co Stoke the shield/crown style mark is based on that used by the predecessor G. T. Mountford |

produced by Myott, Son & Co at the Alexander Works, Wolf Street, Stoke between 1898 and 1902

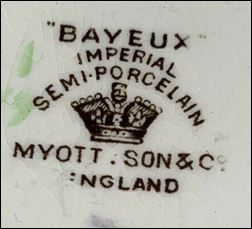

Pair of vases in the Bayeux pattern

Imperial Semi Porcelain

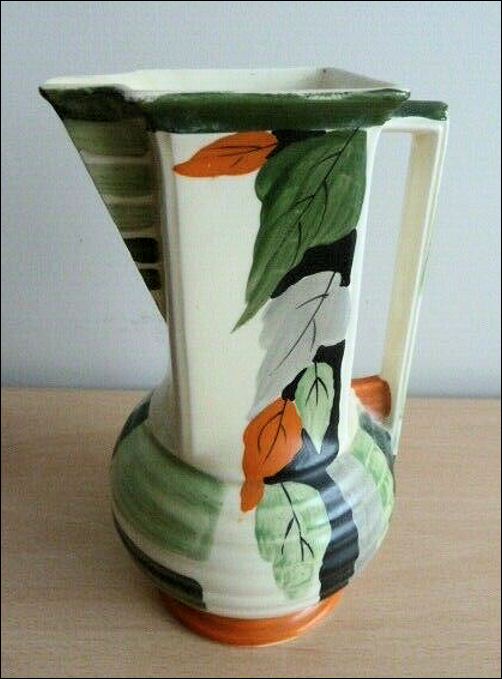

hand painted Art Deco style vasethe registration number shows that the pattern was registered in 1928

Plate in the Royal Crown Range

the pattern is 'The Bouquet'

the Royal Crown range was introduced c.1930

photos courtesy: Chris & Sandra Morgan |

|

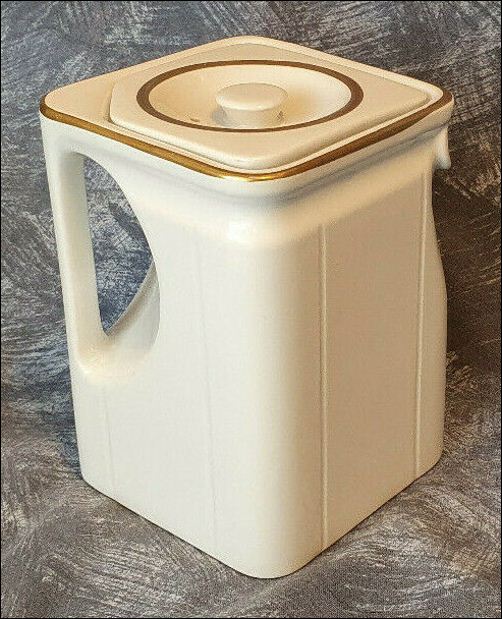

Cube teapot produced by Myott

for the Cunard ocean liners

Made in England

by Goldscheider

with Myott Son & Co

Staffordshire

|

From around 1940 to 1950 Marcel Goldscheider ( an Austrian migrant figure modeller) was based at Myott's works and Myott produced ware to his design and on his behalf. After the fire at the Myott factory in August 1949 Goldscheider moved to his own works in John Street, Hanley. |

sauce boat and saucer - Dior

design

part of the

"China-Lyke" range

introduced c.1959

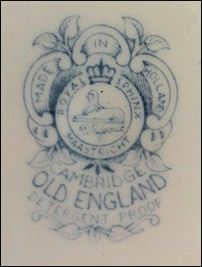

Bowls in the OLD ENGLAND series

one produced by Royal Sphinx in Holland

and one produced by Myott, Son & Co in England

Made in Holland

Royal Sphinx

Maastricht

Cambridge

OLD ENGLAND

Made in England

Myott, Son & Co

Staffordshire

Cambridge

OLD ENGLAND

Identical pattern produced by Royal Sphinx in Holland and Myott, Son & Co in England.

It is probable that the pattern was licenced by Myott to Royal Sphinx and the transfer plates produced by the same engraver.photos courtesy: Allá Popova

Marks used on ware for identification:

M S & Co

MYOTTS

Myott Son & Co

Royal Crown

Old England

M S & Co

Stoke

1898 - 1902

DUDLEY is the pattern name

the shield/crown style mark is based on

that used by the predecessor G. T.

Mountford

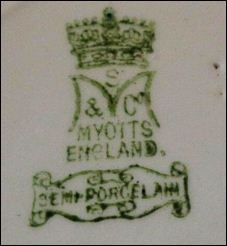

M S & Co England c.1900+

|

M S & Co England c.1900+ the mark appears with and without the words 'Semi Porcelain' |

Impreial Semi Porcelain Myott Son & Co England c.1907+ BAYEUX is the pattern name |

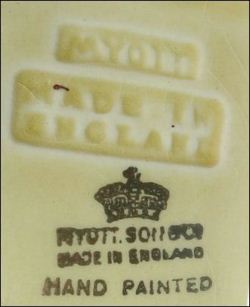

Myotts Royal Crown Staffordshire England c.1930+ Royal Crown isn't a pattern name - it is a range of ware |

Myott Staffordshire England c.1930+ |

Myott Son & Co Made in England c.1936+ this marks appears with and without the impressed marks or the 'Hand Painted' |

Myott Son & Co Hanley Est : 1880 England's Countryside Made in England |

Myott Son & Co Hanley Est : 1880 Shakespeare Land Made in England |

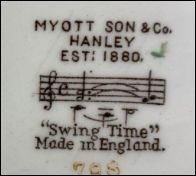

Myott Son & Co Hanley Est : 1880 "Swing Time" Made in England |

in the 1930s Myott launched a range of ware - all of which have Est : 1880

Myott Son & Co were actually

established 1898

- it was the predecessor G. T.

Mountford who was

established in 1880

BY

Myott Son & Co Ltd

Made in England

|

Ware with the BY marks were produced between 1945 and 1952 under the Wartime Concentration Scheme. During

the Second World War production was concentrated in a reduced number of factories in order to save materials, energy and labour as these were needed elsewhere for the war. |

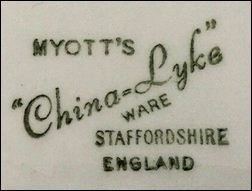

Myott's "China-Lyke" Ware Staffordshire England c.1959+ |

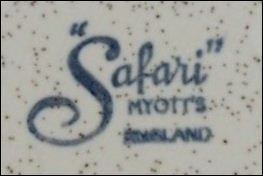

"Safari" Myott's England c.1961+ |

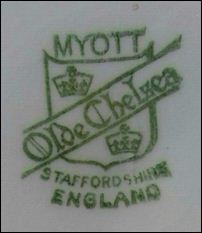

Myott Olde Chelsea Staffordshire England c.1961+ |

MYOTT

England

moulded mark

Factories operated by Myott:

| This summary of the Myott

manufacturing locations should help to clear up some of the confusion

surrounding their factories and location of business.

The Myott business only operated from two locations: 1. The Wolfe Street area of Stoke town - c.1898 to 1902 2. The site of the Brownfield Works on the boundary of Cobridge & Hanley - c.1902 onwards |

Wolfe Street

|

From 1880 the firm of George Thomas Mountford was operating at the Alexander pottery in the area of Stoke town which was to become Wolfe Street. Mountford died 2nd January 1898 and the Myott family purchased the Mountford business. The area around Wolfe Street was being redeveloped in the late 1890s to allow the setting out of streets and building of a market hall. |

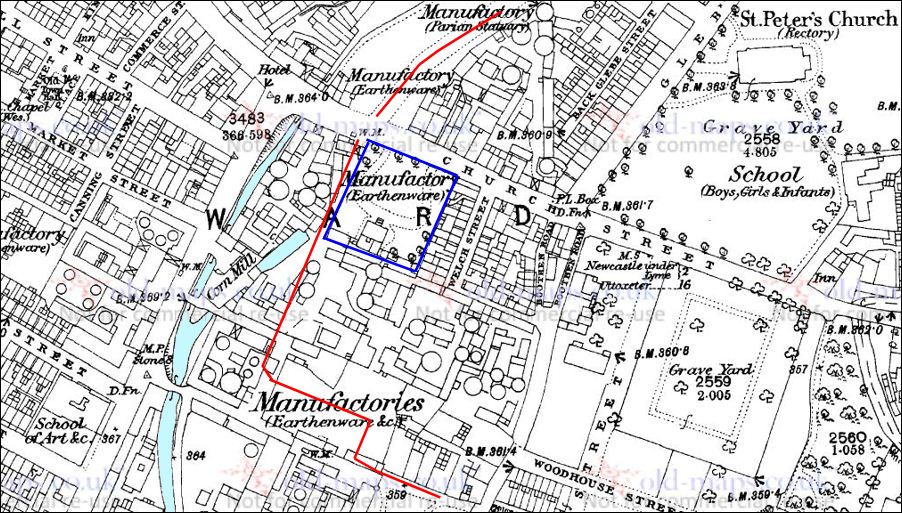

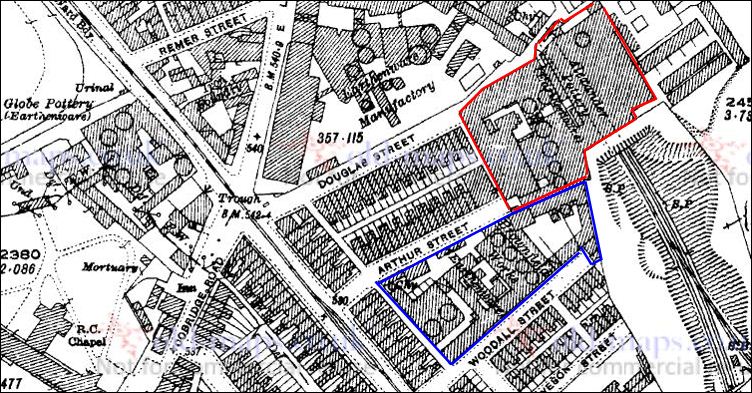

1880 map of Stoke town showing

the area where G. T. Mountford's Alexander

pottery was located

to help locate the area - top right is St.

Peter's Church and to the left is the Newcastle-under-Lyme

canal

the blue square shows a house

and gardens which was to be the location of the market hall

the red line shows the route of the yet to be built Wolfe Street

- it was in this area where the Mountford's Alexander pottery was

located

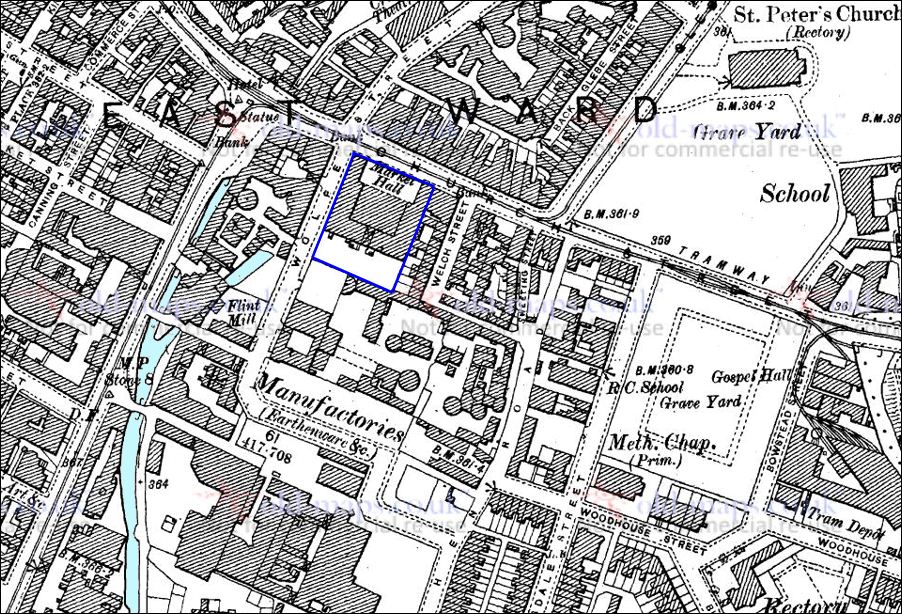

1900 map of the same area

showing the newly laid out Wolfe Street and the Market Hall

it was c.1900 that Myott acquired land on and around the W. Brownfield & Son works in Cobridge

Works at Cobridge

|

William Brownfield had a works at a major crossroads on the outskirts of Cobridge, these works were close to the boundary between Cobridge and Hanley. As

the town of Hanley grew in size and importance this area was, although

strictly in Cobridge, sometimes refered to as Hanley.

|

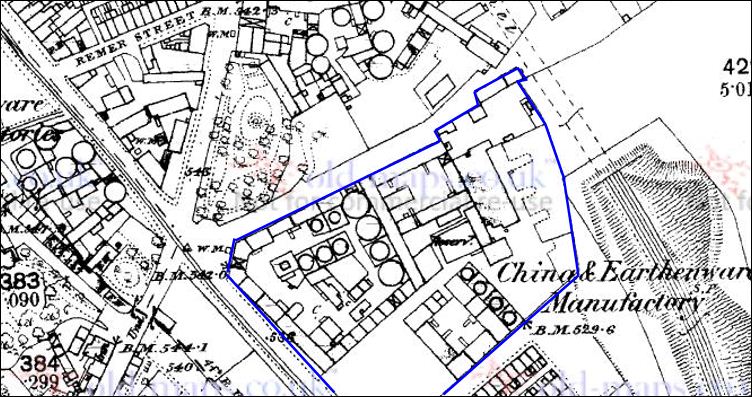

1880 map showing the extensive

Brownfield Works at the crossroads in Cobridge

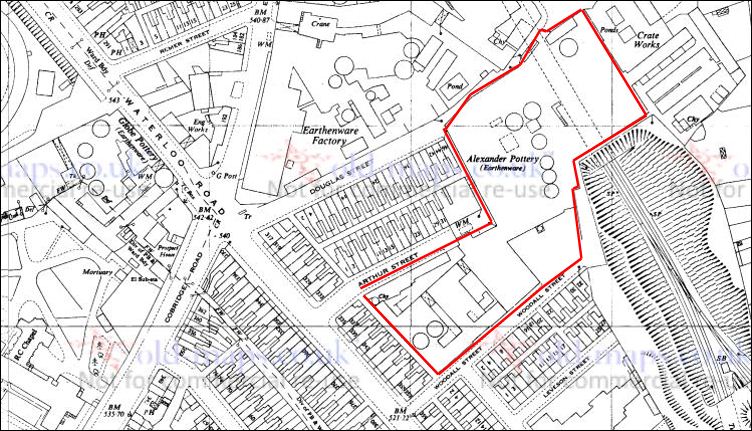

1924 map showing the devopment

of housing and the setting out of Douglas and Arthur Streets

the reduced Brownfield Works and the Alexander Pottery are shown

| In 1900 part of the

extensive Brownfield works in

Cobridge was demolished for housing development, some of the land was

acquired by Myott, in 1902 they had completed a new factory which they

also named the Alexander pottery (after the original works in Wolfe

Street, Stoke).

The Brownfield Works (reduced in size following the development of the area) was occupied by the Upper Hanley Pottery (Grimwades Ltd.) who operated there until c.1911. |

1951 map showing the much

expanded Alexander Pottery

|

In 1925 Myott expanded their works to include the adjacent Brownfield Works - the combined works was called the Alexander Potteries. In the early 1950's Arthur Street was renamed Crane Street. |

Courtesy: Old-Maps.co.uk

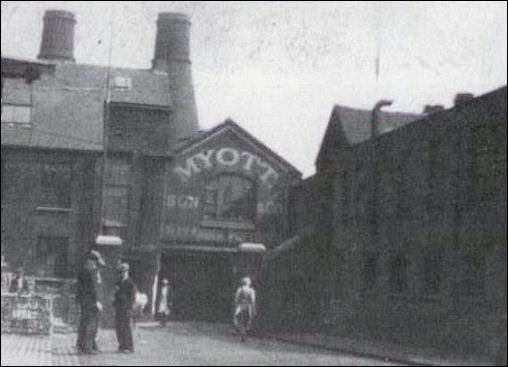

Myott Son & Co

Alexander Potteries

Arthur Street in the 1930's

- click for more information -

Myott Son & Co

Alexander Potteries

Crane Street in 1963

the frontage was refurbished

following the fire in 1949

Arthur Street was renamed to Crane Street in the early 1950's

Courtesy: Staffordshire Past Track

Questions, comments, contributions? email: Steve Birks