![]()

|

Taylor, Tunnicliff & Co Taylor, Tunnicliff & Co (1901) Ltd |

Location and period of operation:

|

Taylor,

Tunnicliff & Co |

Hanley |

1867 |

present (2025)

|

| NOTE: Around 1896 company started to produce porcelain for electrical insulators and

by 1898 production was almost exclusively focused on industrial

ceramics. Earthenware and china manufacturer at Eastwood, Hanley and the Albion Works in Longton, Stoke-on-Trent, England.

|

jump to:

| London Gazette notices | Typical Ware | Identification marks |

| Electrical Insulators | Biography of Thomas Taylor | Factories |

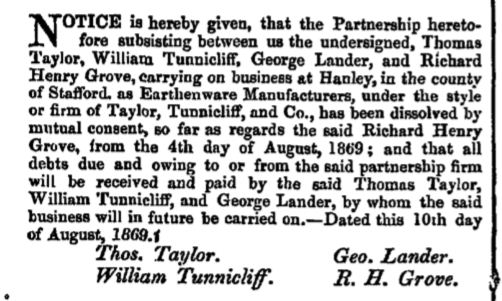

The London Gazette

24 August 1869

notice that Richard Henry Grove

had retired from the business

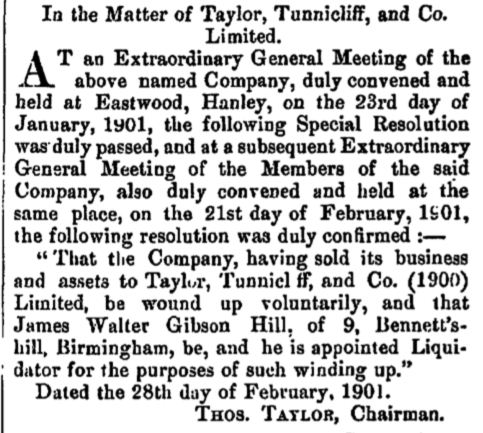

The London Gazette

12 March 1901

notice that the business and

assets be sold to

Taylor, Tunnicliff and Co (1901) Ltd

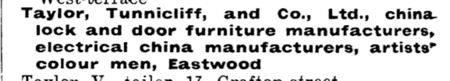

Taylor, Tunnicliff, and Co.,

Ltd.,

china lock and door furniture manufacturers,

electrical china manufacturers, artist'

colour men, Eastwood

from..... 1907

Staffordshire Sentinel

'Business Reference Guide to The Potteries, Newcastle & District'

|

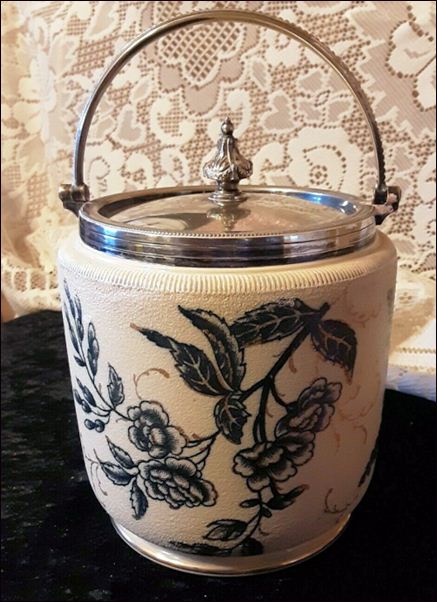

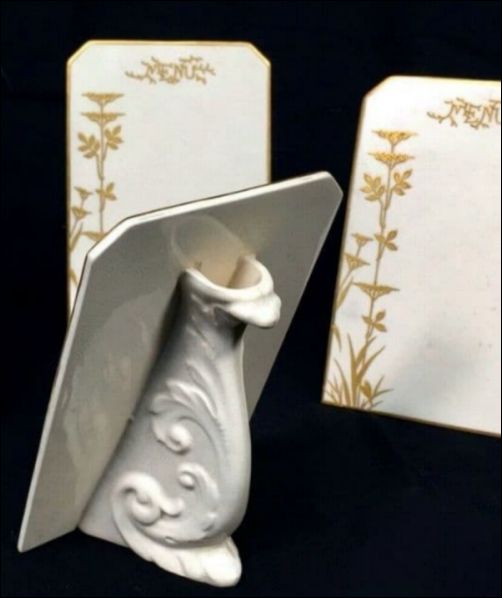

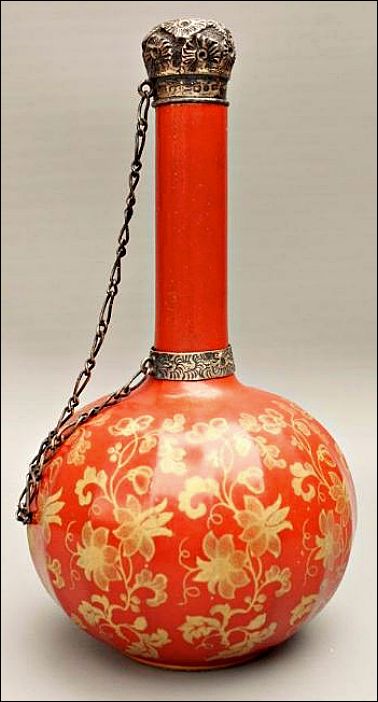

Typical ware: Between 1867 and 1898 Taylor, Tunnicliff & Co produced quality ware, often with gilt decoration. They produced oil lamps and a wide range of biscuit barrels and other ware with silver and silver-plate metal lids and rims. After 1898 they focused on manufacturing 'utilitarian' objects, especially electrical insulators. Although in March 1901 they did register the design of a salad, biscuit and condiment set (reg no: 371386). |

biscuit barrel

Taylor, Tunnicliff & Co

produced a wide range of biscuit barrels and other

ware with silver-plate metal lids

sauce boat in the European

Imari style

vase for single flower bud |

perfume bottle in an oil-lamp design |

whisky decanter |

pin dish (4 inch dia)

in the Willow pattern

ceramic table menu card holders

with posy flower spill vases to the back

the registration diamond shows that the design was registered on the 25th October 1883

oil lamp by Taylor, Tunnicliff & Co with a Hinks & Son's Patent burner |

Rd 43323 the lamp is not marked with Taylor, Tunnicliff but has a registration number which shows that the design for the shape of the lamp base was registered by them on 17th February 1886 - described as "a lamp base of wasted form, the lower part of inverted baluster shape, the upper of baluster form but with a groove near the top, milled opening at the top for metal mount" (courtesy: Northern Ceramic Society) |

pair of oil lamps by Taylor, Tunnicliff & Co the lamps incorporate the Hinks & Son's Patent oil burner |

constituent parts of the lamp

|

photos courtesy: Tony Clarke

|

typical mark with intertwined letters for Taylor, Tunnicliff & Co |

|

unusual mark but the registration number and the bottle shape show that it was made by Taylor, Tunnicliff & Co |

| decorated with a deep burnt orange ground and floral gilding - the silver mounts have the Birmingham stamp for 1887 |

same

shape scent bottle, decorated with gold freckle on a brown

background photos courtesy: Beth Ingram |

the registration number 79841 shows that the design for this scent bottle shape was registered by Taylor Tunnicliff on the 31st August 1887 which is described as "a scent bottle of globular fluted body with tall cylindrical neck, the neck rim milled for metal mount" (courtesy: Northern Ceramic Society) |

|

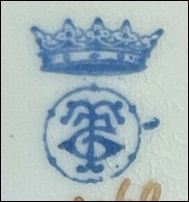

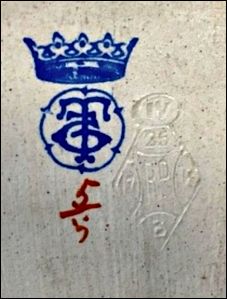

Marks used on ware for identification:

Difference between the marks of Taylor, Tunnicliff & Co and Thomas Cone

|

Taylor, Tunnicliff & Co.

|

Thomas Cone

NOTE: this mark is not that of Taylor, Tunnicliff & Co. - it is that of Thomas Cone. |

|

Confusion can arise between the marks of Taylor, Tunnicliff & Co and Thomas Cone because of the similarity of the overlapping letters. The Taylor, Tunnicliff monogram has two letter 'T's, usually inside a circle and often has a crown above. The Thomas Cone monogram has one letter 'T' always has the town name 'LONGTON' and never has a crown. |

|

Taylor, Tunnicliff & Co

Taylor,

Tunnicliff & Co

typical marks

with the intertwined letters T T C

and crown above

c.1875-98

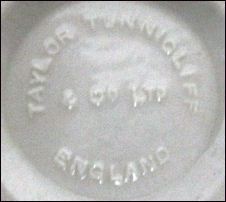

Taylor Tunnicliff

& Co Ltd

England

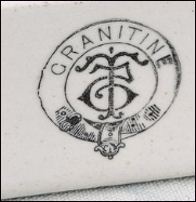

Granitine was a trade mark used for darkroom porcelain

|

Granitine was a trade mark used by Taylor, Tunnicliff & Co for porcelain ware for photographic film developing and processing. |

T T & Co

England

mark generally used on electrical porcelain

|

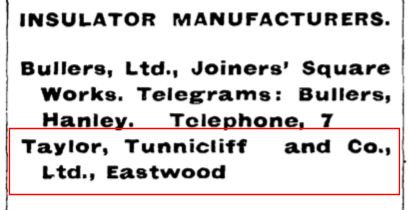

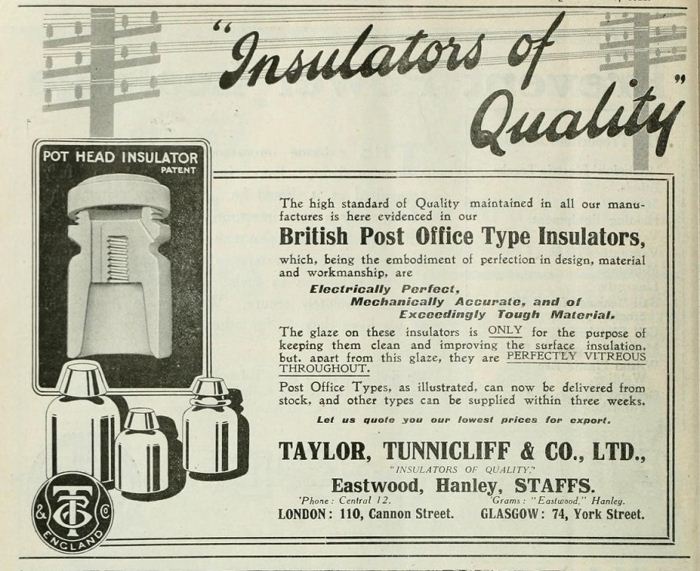

Electrical insulators: From 1898 Taylor, Tunnicliff & Co focused almost entirely on manufacturing industrial ware, particularly electrical insulators. |

1922 advert for Taylor, Tunnicliff & Co Ltd "Insulators of Quality"

courtesy: Grace's Guide

Taylor Tunnicliff

Porcelain Insulation

Prestige and Progress - A Survey

of Industrial North Staffordshire

1955 publication of North Staffordshire Chamber of Commerce - page 70

low voltage electrical insulator by Taylor, Tunnicliff & Co |

typical T T & Co England mark |

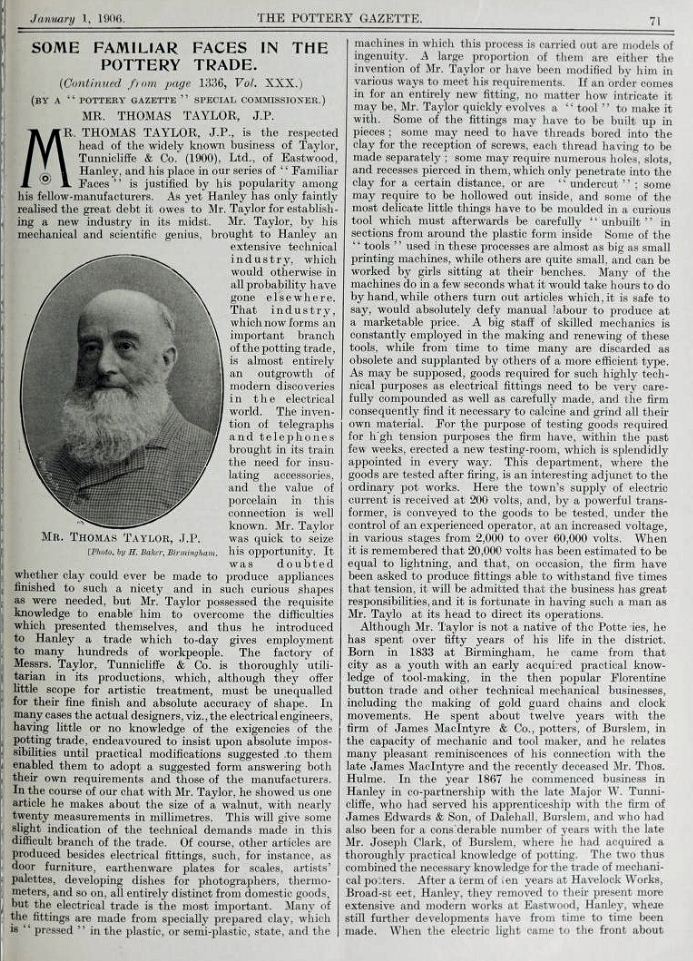

The Pottery Gazette

January 1 1906

article on Mr. Thomas Taylor, J.P. and the Taylor, Tunnicliff company

Note the misspelling of the name Tunnicliff (which does not have a letter 'e' at the end')

|

THOMAS TAYLOR, J.P., is the respected head of the widely known business of Taylor, Tunnicliffe & Co. (1900), Ltd., of Eastwood, Hanley, and his place in our series of "Familiar Faces" is justified by his popularity among his fellow-manufacturers. As yet Hanley has only faintly realised the great debt it owes to Mr. Taylor for establishing a new industry in its midst. Mr. Taylor, by his mechanical and scientific genius, brought to Hanley an extensive technical industry, which would otherwise in all probability have gone elsewhere. That industry, which now forms an important branch of the potting trade, is almost entirely an outgrowth of modern discoveries in the electrical world. The invention of telegraphs and telephones brought in its train the need for insulating accessories, and the value of porcelain in this connection is well known. Mr. Taylor was quick to seize his opportunity. It was doubted whether clay could ever be made to produce appliances finished to such a nicety and in such curious shapes as were needed, but Mr. Taylor possessed the requisite knowledge to enable him to overcome the difficulties which presented themselves, and thus he introduced to Hanley a trade which to-day gives employment to many hundreds of workpeople. The factory of Messrs. Taylor, Tunnicliffe & Co. is thoroughly utilitarian in its productions, which, although they offer little scope for artistic treatment, must be unequalled for their fine finish and absolute accuracy of shape. In many cases the actual designers, viz., the electrical engineers, having little or no knowledge of the exigencies of the potting trade, endeavoured to insist upon absolute impossibilities until practical modifications suggested to them enabled them to adopt a suggested form answering both their own requirements and those of the manufacturers. In the course of our chat with Mr. Taylor, he showed us one article he makes about the size of a walnut, with nearly twenty measurements in millimetres. This will give some slight indication of the technical demands made in this difficult branch of the trade. Of course, other articles are produced besides electrical fittings, such, for instance, as door furniture, earthenware plates for scales, artists’ palettes, developing dishes for photographers, thermometers, and so on, all entirely distinct from domestic goods, but the electrical trade is the most important. Many of the fittings are made from specially prepared clay, which is "pressed" in the plastic, or semi-plastic, state, and the machines in which this process is carried out are models of ingenuity. A large proportion of them are either the invention of Mr. Taylor or have been modified by him in various ways to meet his requirements. If an order comes in for an entirely new fitting, no matter how intricate it may be, Mr. Taylor quickly evolves a "tool" to make it with. Some of the fittings may have to be built up in pieces ; some may need to have threads bored into the clay for the reception of screws, each thread having to be made separately ; some may require numerous holes, slots, and recesses pierced in them, which only penetrate into the clay for a certain distance, or are "undercut" ; some may require to be hollowed out inside, and some of the most delicate little things have to be moulded in a curious tool which must afterwards be carefully "unbuilt" in sections from around the plastic form inside. Some of the "tools" used in these processes are almost as big as small printing machines, while others are quite small, and can be worked by girls sitting at their benches. Many of the machines do in a few seconds what it would take hours to do by hand, while others turn out articles which, it is safe to say, would absolutely defy manual labour to produce at a marketable price. A big staff of skilled mechanics is constantly employed in the making and renewing of these tools, while from time to time many are discarded as obsolete and supplanted by others of a more efficient type. As may be supposed, goods required for such highly technical purposes as electrical fittings need to be very carefully compounded as well as carefully made, and the firm consequently find it necessary to calcine and grind all their own material. For the purpose of testing goods required for high tension purposes the firm have, within the past few weeks, erected a new testing-room, which is splendidly appointed in every way. This department, where the goods are tested after firing, is an interesting adjunct to the ordinary pot works. Here the town’s supply of electric current is received at 200 volts, and, by a powerful transformer, is conveyed to the goods to be tested, under the control of an experienced operator, at an increased voltage, in various stages from 2,000 to over 60,000 volts. When it is remembered that 20,000 volts has been estimated to be equal to lightning, and that, on occasion, the firm have been asked to produce fittings able to withstand five times that tension, it will be admitted that the business has great responsibilities, and it is fortunate in having such a man as Mr. Taylor at its head to direct its operations. Although Mr. Taylor is not a native of the Potteries, he has spent over fifty years of his life in the district. Born in 1833 at Birmingham, he came from that city as a youth with an early acquired practical know ledge of tool-making, in the then popular Florentine button trade and other technical mechanical businesses, including the making of gold guard chains and clock movements. He spent about twelve years with the firm of James MacIntyre & Co., potters, of Burslem, in the capacity of mechanic and tool maker, and he relates many pleasant reminiscences of his connection with the late James MacIntyre and the recently deceased Mr. Thos. Hulme. In the year 1867 he commenced business in Hanley in co-partnership with the late Major W. Tunnicliffe, who had served his apprenticeship with the firm of James Edwards & Son, of Dalehall, Burslem, and who had also been for a considerable number of years with the late Mr. Joseph Clark, of Burslem, where he had acquired a thoroughly practical knowledge of potting. The two thus combined the necessary knowledge for the trade of mechanical potters. After a term of ten years at Havelock Works, Broad-street, Hanley, they removed to their present more extensive and modern works at Eastwood, Hanley, where still further developments have from time to time been made. When the electric light came to the front about |

|

|

twenty-five years ago, they at once saw the possibilities it offered for the future, and from that time onwards they have been in the first rank in the manufacture of this class of goods, for the supply of which they are on the list of various Government and Colonial departments. Mr. Taylor and Mr. Tunnicliffe continued the dual control of the business until shortly before the retirement of Mr. Tunnicliffe some years ago, when the business was converted into a private limited liability company, with Mr. Taylor as chairman. Mr. Taylor has the reputation of being one of the most kindly and considerate employers in North Staffordshire, and, in particular, he pays special attention to the welfare of his lead workers. So efficacious are the precautions taken to safeguard the workers in this department that there has not been a genuine case of plumbism there for about four years. The cleaners after the dippers are not only provided with specially shaped dishes filled with half an inch of water, into which all heavy particles of moist glaze fall at once, but all round the room under the work bench runs an air conduit, with a powerful fan working at the outlet. This fan sucks the air away from the workers, and any particles of dry glaze which remain in suspension are at once drawn into the conduit, and thence ejected into the open air outside. A piece of paper held in the hand near the cowl where the cleaners sit will at once flutter towards the conduit, demonstrating its effectiveness for the purpose for which it is designed. Mr. Taylor is, at the present moment, bringing plans of this room under the special notice of the Joint Committee of Manufacturers, of which he has been a member since the first Home Office inquiry in 1896. He then advocated the periodical examination of the male workers as well as the females, and this has since come about. He also made many other suggestions, in the matter of ventilation, and so on, which proved of he greatest value to the Home Office. Mr. Taylor enforced the examination of all his female workpeople in the lead departments long before this became compulsory, and for years paid a doctor to examine his workpeople, with excellent results. He has also well-appointed messrooms for lead workers, and cooking kitchens for the other workpeople. Mr. Taylor was placed on the Commission of the Peace for Hanley on May 23, 1887. He was a member of the School of Art Centre until the Town Council took the control of the Art School into its own hands. He has done much for the development of musical taste in the district, and was greatly interested in the old Hanley Philharmonic Society and Male Voice Choir. He is an "Alderman" of the organisation known as the Hanley "Anciente Corporatione," and on one occasion presided at its annual venison feast, which has been perpetuated now for 122 years. He has also presented the "Corporatione" with a very handsome wassail bowl of earthenware and a beautiful silver loving cup, ladle, &c. Upwards of 40 years have elapsed since Mr. Taylor’s connection with Freemasonry began. He was initiated a member of the Menturia Lodge, Hanley, in 1865, and was installed Master in 1870. At that time the Province of Staffordshire was without a Provincial Grand Master. Mr. Taylor took the first steps to bring the name of the late Earl of Shrewsbury forward to fill that office, and he was accepted by the Grand Master of England, appointed, and installed during Mr. Taylor’s year of office. From that date until his death in 1877 his Lordship took a prominent part in Masonry, and was President of the Staffordshire Masonic Charitable Association. In 1873 his Lordship appointed Mr. Taylor Provincial Grand Warden of Staffordshire, the highest honour in his power to bestow. In 1885 Mr. Taylor took the first steps to establish a second lodge — the Gordon — in Hanley. It was consecrated on March 30, 1886. The new lodge has since fully justified the efforts of its founders, and now holds a prominent position in the Province, more especially in regard to its support of the

Masonic charities. In 1895 Mr. Taylor was elected Worshipful Master of the Gordon Lodge, in

celebration of the lapse of a quarter of a century since he was in the chair of the Menturia Lodge, and it is remarkable that Mr. E. E. Scrivener and Mr. T. Bickley, J.P., who were his wardens in 1870, occupied a similar position at his second installation. They are both living to-day, and have been associated with Mr. Taylor in

Masonic work for forty years. In 1903 Mr. Taylor was appointed Grand Junior Deacon of England, and he has also held grand honours in Supreme Grand Chapter of England and Great Priory of England of the Order of Masonic Knights Templar, and other

Masonic orders. He has always been an active and prominent supporter of Masonic

charities, having qualified for his first stewardship of the festival of the Royal Masonic Institution for Girls in 1874, when the late Lord Shrewsbury presided, and the Masons of Staffordshire presented the Institution with a complete new outfit of Staffordshire

earthenware for the use of the schools. Since that time his donations to the three London central institutions — the Royal Masonic Institutions for Girls and Boys and the Royal Benevolent Institution for aged and infirm Freemasons and widows of Freemasons — have qualified him as vice-patron of each. He also gave a donation of 500 guineas in one sum towards the purchase of a perpetual presentation

scholarship to the Royal Masonic Institution for Girls, which gives the Province of Staffordshire a presentation — known, after Mr. Taylor, as the

"Taylor Scholarship" — of one girl in perpetuity, at a cost of 1,500 guineas. Since the establishment of the Staffordshire Masonic Charitable Association, in 1871, he has been a regular supporter and worker in connection with it, and was appointed its President in 1898, during which year the great centenary festival of the Royal Masonic Institution for Boys took place, when

over £130,000 was subscribed by Freemasons under the Grand Lodge of England, by means of which the splendid institution at Bushey was built, to accommodate

nearly 500 boys. Mr. Taylor is now a member of the Board of Management of this institution. |

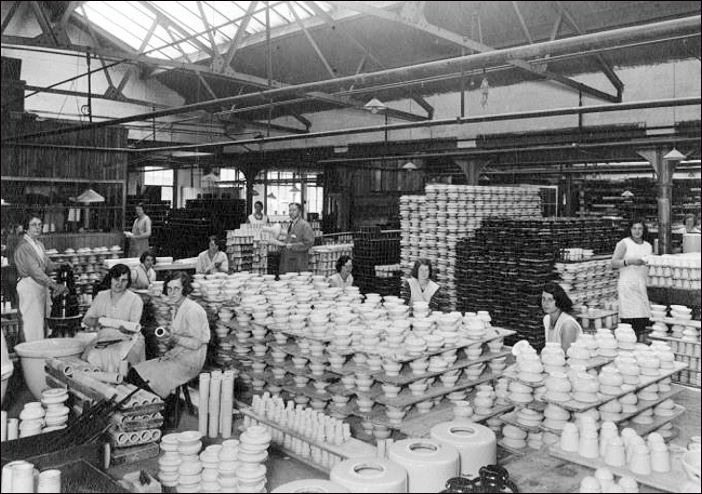

Taylor Tunnicliff Factories

The selection warehouse at

Taylor, Tunnicliff's Eastwood factory, Hanley

Image courtesy of: Mr Phillip Leason

photo: 1930 - Staffordshire Past Track

The Albion Works between

Normacot Road and Uttoxeter

Road, Longton

St. James Church is on the left

photos: 1953 Britain from Above

The Taylor Tunnicliff

Electrical Porcelain Factory, Stone

the Trent & Mersey Canal is to the top of the works

photos: 1953 Britain from Above

Questions, comments, contributions? email: Steve Birks

|

Page created 21 Jul 2021 Updated 23 May 2025: Introduction significantly expanded; 1906 Pottery Gazette article added; section on electrical insulators added. Last updated 16 December 2025: Clarification on confusion between marks of Taylor, Tunnicliff & Co and those of Thomas Cone expanded. |