Location and

period of operation:

|

Doulton

& Co

|

Burslem

(and

other locations)

|

1882

|

Jan 2005

|

|

Doulton began as a partnership between

John Doulton, Martha Jones, and John Watts, at a factory in Lambeth,

London in 1815. They specialised in making stoneware

articles, such as decorative bottles and salt glaze sewer pipes. The company took

on the Doulton name in 1853 when John, and his son Henry,

established themselves as makers of fine English stoneware.

Manufacturing continued here until 1956.

-

In 1877 Henry Doulton became a partner

in a failing pottery company: Pinder, Bourne and Co at Nile Street in

Burslem. In the same year Henry Doulton was knighted, a few years later he was awarded the Albert Medal by the Royal Society of Arts.

-

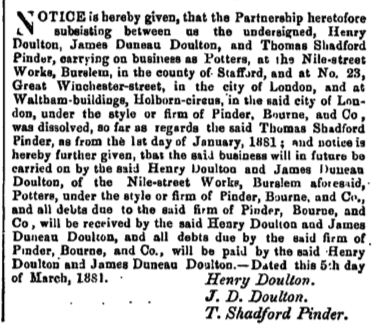

The

Pinder/Doulton partnership was not a success and in March 1881

Thomas Shadford Pinder retired and the business was continued by Sir

Henry Doulton and his brother, James Duneau Doulton. Also in 1881

Henry's only son, Henry Lewis Doulton was made a partner.

-

The name of Pinder, Bourne & Co. continued to be used until 1882 when it became Doulton & Co.

The

London Gazette

8th March 1881

notice that Thomas

Shadford Pinder retired from the partnership

of Pinder, Bourne & Co and the business was continued

by Henry Doulton and his brother, James Duneau Doulton.

-

James

Duneau Doulton died in 1889 and Sir Henry Doulton died in 1897. The

business continued under the leadership of Henry's son, Henry Lewis

Doulton.

-

In

1899 the business was incorporated as Doulton & Co. Ltd. On the incorporation of the business

Henry Lewis Doulton assumed the positions of Managing Director and first Chairman of Doulton & Co.

Ltd.

-

In

1901 the Royal Warrant was granted by King Edward VIII.

-

In

1919 Henry Lewis Doulton's nephew, Lewis John Eric Hooper, took

over the position of Managing Director and he also became Chairman in

1925 when Henry Lewis Doulton retired. Lewis Hooper remained chairman

until 1955.

-

Doulton

& Co (Burslem) remained open during the Second World War under the Wartime

Concentration Scheme - they were permitted to produce

undecorated domestic ware. They also produced canteen ware for the British

armed forces.

-

In

June 1945 Doulton & Co (both Burslem & Lambeth factories) were

granted a licence to produce 'fancies'

for the home market.

-

In

1955-56 the Doulton group was restructured in January 1956 four

divisions were created: Doulton Fine China Ltd who manufactured

earthenware and china ware at Nile Street, Doulton Sanitary Potteries

Ltd, Doulton Industrial Porcelains Ltd and Doulton Vitrified Pipes

Ltd. At this time the Lambeth, London studios were closed.

-

In

1968 Doulton took over the businesses of Mintons

Ltd and Dunn Bennett and Co Ltd

and the following year took over John

Beswick Ltd and also acquired the Stourbridge based glass

manufacturing company of Webb Corbett Ltd.

-

In

November 1971 S.

Pearson & Son (Ltd) - who were already owners of Allied

English Potteries Ltd - acquired Doulton & Co Ltd and merged

the two groups under the Doulton name.

-

In

August 1972 it was announced that "Allied English Potteries will

become a subsidiary of Doulton and its name will be changed to Royal

Doulton Tableware Ltd.

|

"From

January 1973 the new company became custodian of the tableware and

giftware assets of the two groups including the Royal Doulton,

Minton, Beswick, Dunn Bennett, Booths, Colclough, Royal Albert,

Royal Crown Derby, Paragon, Ridgway, Queen Anne, Royal Adderley

and Royal Floral names and their vast manufacturing

operations.

The

company also held the 50 Lawley

china and glass retail stores inherited from Allied English

Potteries.

Royal

Doulton Tableware Ltd was a subsidiary of Doulton & Co Ltd,

itself a subsidiary of the Pearson Group. The name was in use

until at least 1983 and probably until the float of Royal Doulton

PLC in 1993"

'A Handbook of British Pottery Manufacturers 1900-2010'

Michael Perry

|

-

December

1992 saw a floatation on the London Stock Exchange and the formation

of Royal Doulton PLC.

-

Poor

financial performance saw the sale of certain subsidiaries and

substantial rationalisation. In spite of this action losses continued

and with estimated debts of £26m, 2002 saw the closure of Doulton's

Baddeley Green factory with the loss of 500 jobs and the transfer of

the production of 'Royal Albert'

to Indonesia. Later in 2002 the Beswick Gold Street works in Longton

was also closed with the loss of 200 jobs. (BBC

News).

-

In

March 2004 it was announced that the original Nile Street works, the

only remaining Doulton UK manufacturing facility, would be

closed.

-

In

February 2005 Waterford Wedgwood, who already had a large stake in

Doulton shares, completed a nearly £40m take over of of Royal Doulton

PLC.

-

In

April 2005 manufacturing at the Nile Street works ceased and

production of the Royal Doulton, Minton and Royal Albert brands was transferred

to factories of the Waterford Wedgwood group - most of which

were overseas.

|

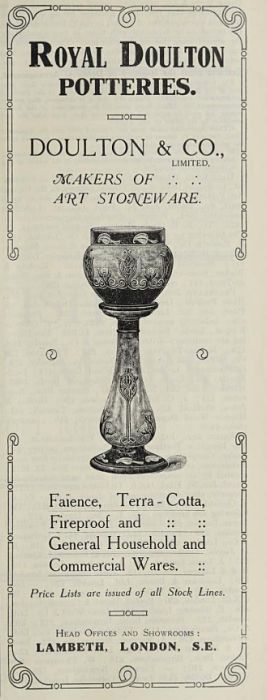

previously: Pinder, Bourne and Co

Royal Doulton Potteries

Doulton & Co Limited

Makers of Art Stoneware

The Pottery Gazette - February

1913

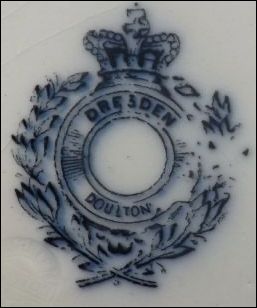

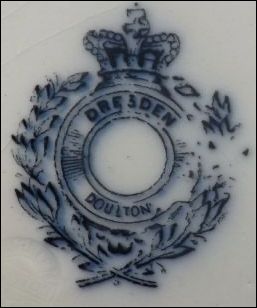

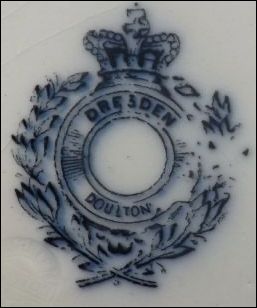

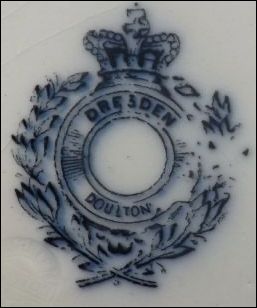

plate in the

Dresden pattern- based on the popular Indian Tree pattern

this pattern was started by Pinder,

Bourne & Hope and continued

by Pinder, Bourne & Co and subsequently Doulton

& Co |

Dresden

Doulton

printed mark - the design continued

from the previous Pinder partnerships - at the bottom left is an

impressed mark

Doulton

Burslem

England

|

photos courtesy:

Rod Crowshaw

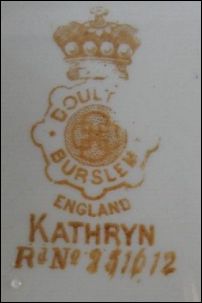

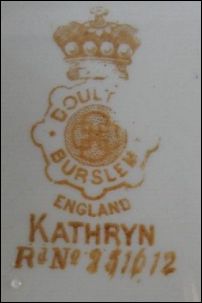

serving platter in the

Kathryn pattern

dinner services were produced in this

popular pattern which was available in a monochrome printed pattern and

also with hand painted colour and gilt accents |

Doulton

Burslem

England

Rd No 251612

the registration

number shows that his pattern was registered by Doulton &

Co

on the 20th March 1895

impressed Doulton mark with the month-year

of manufacture 1-96 (January 1896)

|

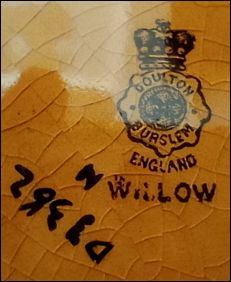

Doulton syrup jug with

drip plate in a black willow style print with mustard glaze |

Doulton

Burslem

England

pattern

no: D3382

c.1891-1902

(mark

on the drip tray) |

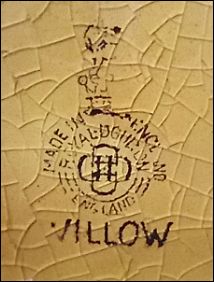

Made in England

Royal Doulton

England

c.1930+

Godden

notes that "'Made in England' added from c.1930 onwards"

(mark

on the jug) |

Photos courtesy: Evangelina

Escudero

tobacco jar in the

Holbein glaze

“Number D1781; Pattern number LL2353; Tobacco jar; Virginia; Red u/g orange block prints, laurel borders; Holbein Glaze No 2; Gold edge, foot line & [?] lines”. This entry is dated 16 November 1903"

source: Royal Doulton Archive

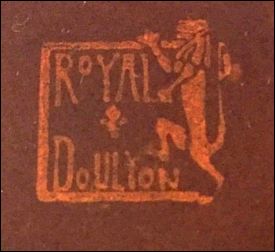

|

Royal

Doulton

unusual,

un-catalogued mark

(contrast

has been altered to make mark clearer)

|

photos courtesy:

Markus Winter

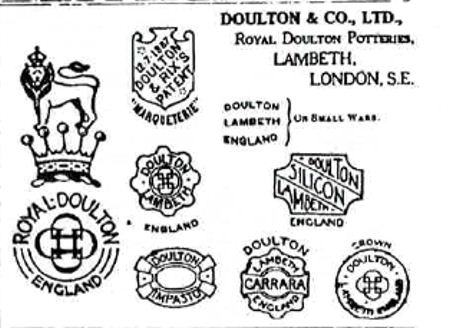

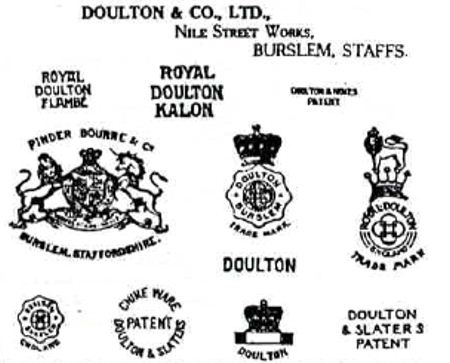

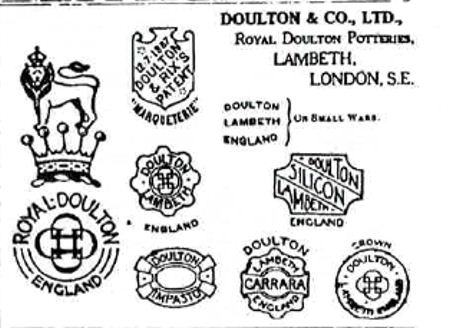

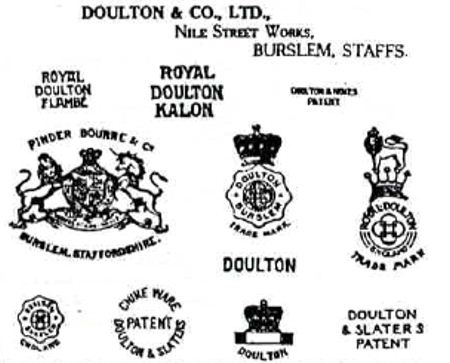

Marks used on

ware for identification:

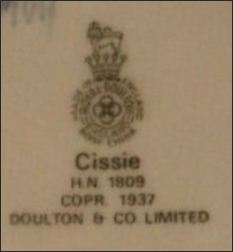

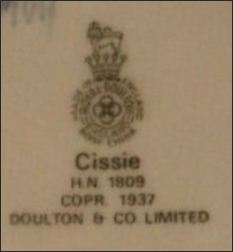

Doulton & Co., Ltd.,

Royal Doulton Potteries

Lambeth, London, S.E.

from 1917 Pottery Gazette Diary

Doulton & Co., Ltd.,

Nile Street Works

Burslem, Staffs

from 1917 Pottery Gazette Diary

Dresden

Doulton

and early printed mark - the wreath and

crown design continued from the previous Pinder partnerships - at the

bottom left is an impressed mark

|

Doulton

Burslem

England

the impressed mark - the inclusion of

'England' generally indicates a date post 1891

|

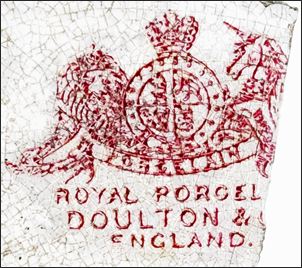

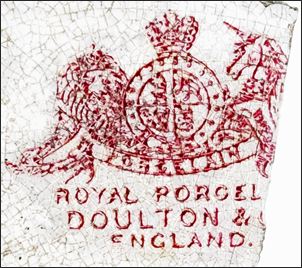

Royal Porcelain

Doulton & Co

Englandexample

of the use of faux Royal

Arms - continued from the predecessor Pinder, Bourne and Co

c.1891

-1902

|

The plate is 12 inches in diameter the

decoration is repeated four times around the border with a scalloped

section between each. |

"fragment from a plate at

the site of the Stoney Creek Falls Hotel,

Cairns, Queensland, Australia. This hotel operated between 1887 and 1890"

Doulton

Burslem

c.1882-1891

marks prior to 1891 generally

didn't include ENGLAND

this mark also appeared without the crown above

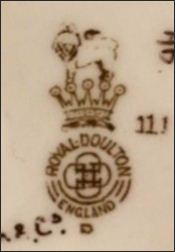

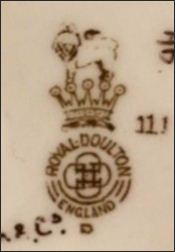

Royal Doulton

England

standard trade mark introduced c.1902

after the Royal Warrant was granted by

King Edward VIII. in 1901

|

Made in England

Royal Doulton

England

marks including "Made in

England"

from c.1930+ |

Doulton

war-time output:

G VI R

Doulton & Co Ltd

1942

|

The

mark shown indicates that the ware was produced for and supplied to the

British Government; it was ultimately property of the Crown/Government,

hence the GR-VI Cypher.

This mark is there to distinguish the piece from being normal ‘utilitarian’ ware for public sale

during the period surrounding the

Second World War.

Doulton

& Co (and others) were given government contracts throughout the late 1930s

and into the 1940s (WWII) and produced canteen ware - most likely for

the armed services.

The

year of manufacturer is generally included. |

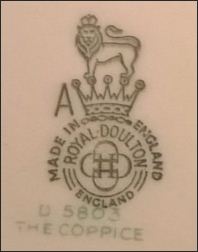

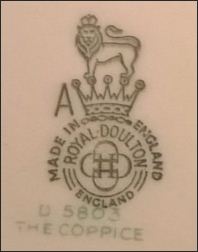

c.1942-52

the inclusion of the letter A

indicates that the ware was made

under the provisions of the Wartime

Concentration Scheme

Post 1960

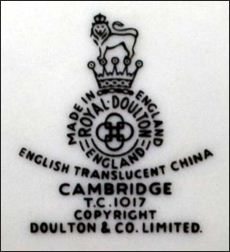

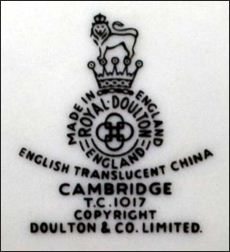

marks:

Royal Doulton, England

Made in England

English Translucent China

Doulton & Co Limited

English Translucent China introduced in

January 1960 |

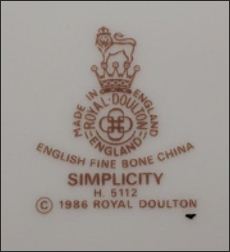

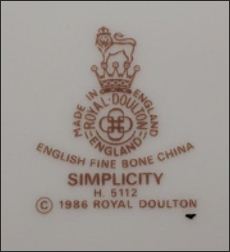

Royal Doulton, England

Made in England

English Fine Bone China

© 1986 Royal Doulton |

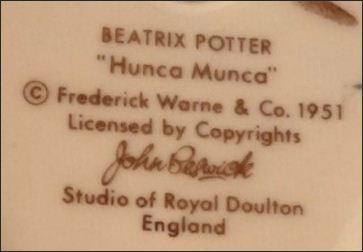

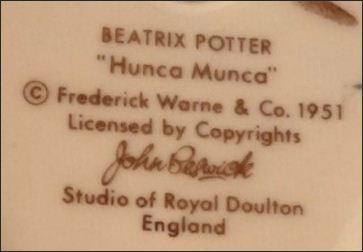

in 1969 Doulton took over John

Beswick Ltd

Fine China

A Royal Doulton Product

Made in Indonesia |

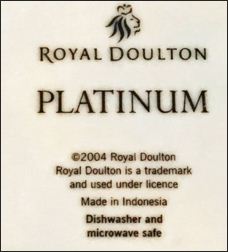

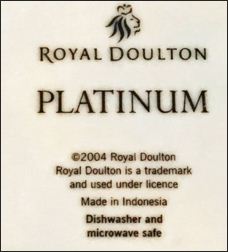

Royal Doulton is

a

trademark and used under licence

Made in Indonesia |

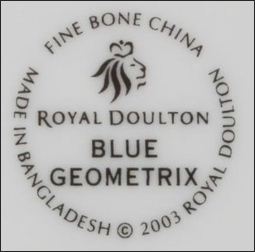

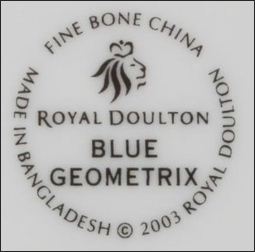

Fine Bone China

Royal Doulton

Made in Bangladesh |

-

2002 saw the closure of Doulton's

Baddeley Green factory with the loss of 500 jobs and the transfer of

the production of 'Royal Albert'

to Indonesia.

-

In

March 2004 it was announced that the original Nile Street works, the

only remaining Doulton UK manufacturing facility, would be

closed.

-

In

February 2005 Waterford Wedgwood, who already had a large stake in

Doulton shares, completed a nearly £40m take over of of Royal Doulton

PLC.

-

In

April 2005 manufacturing at the Nile Street works ceased and

production of the Royal Doulton, Minton and Royal Albert brands was transferred

to factories of the Waterford Wedgwood group - most of which

were overseas.

|

Questions, comments,

contributions?: email Steve Birks

|

Page History:

Page

created 11 October 2022 Last

updated: 28 Oct 2025 |

![]()